11 Refractory Weld Studs Sunbelt Stud Welding Catalog 5e4p67

This document was ed by and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this report form. Report 445h4w

Overview 1s532p

& View 11 Refractory Weld Studs Sunbelt Stud Welding Catalog as PDF for free.

More details 6h715l

- Words: 1,206

- Pages: 14

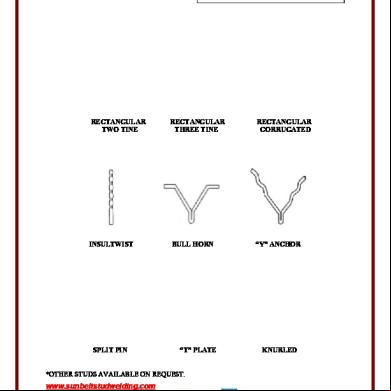

REFRACTORY STUDS

RECTANGULAR TWO TINE

RECTANGULAR THREE TINE

RECTANGULAR CORRUGATED

INSULTWIST

BULL HORN

“Y” ANCHOR

SPLIT PIN

“T” PLATE

KNURLED

*OTHER STUDS AVAILABLE ON REQUEST.

www.sunbeltstudwelding.com Sunbelt Stud Welding, Inc. 6381 Windfern Road Houston, Texas 77040-4915

11-1

1-800-462-9353 713-939-8903 fax 713-939-9013

GENERAL SPECIFICATIONS ARC STUD WELDED ANCHORS

MATERIAL: PLATING: ANNEALING: WELD BASE: STUD LENGTH:

FERRULES:

ARC STUD WELDED REFRACTORY ANCHORS Standard in low carbon steel and 302/304/305 stainless. Monel, inconel, and other grades of stainless steel are available. Plating is not standard. Cium to ASTM A 165, type TS and zinc to ASTM B 633 are available. Non-weldable plating is removed from the weld end to avoid contamination of the weld. Low carbon steel can be annealed to a maximum of 75 Rockwell B and stainless steel to a maximum of 90 Rockwell B. Solid flux is provided where required. SUNBELT arc stud length APPROX. STUD DIAMETER designations are BEFORE WELD. REDUCTION AFTER WELD lengths are shown in 3/16” thru 1/2” 1/8” the table. 5/8” thru 7/8” 3/16” 7/8” and over 1/4” 1/8” wide rectangulars 1/8” All orders include ferrules when they are required.

DEG WITH SUNBELT ARC STUD WELDED REFRACTORY ANCHORS: Advantages: SUNBELT arc stud welded refractory anchors reduce costs and downtime and increase production through speedier installation and improved product quality. Arc stud welding systems are portable and require minimal instruction or maintenance for use. Speed of anchor application and ease of use reduce labor requirements and eliminate other complicated fastening systems while maintaining excellent weld quality and improved refractory holding power.

HOW TO CHOOSE THE PROPER REFRACTORY ANCHOR STYLE: See table on 11-3 MATERIAL: The following temperature limits at the hot face or surface of the refractory, are recommended for anchors of the steel grades shown. STEEL TYPE HOT FACE TEMP. LIMIT Low Carbon Steel 1000° F Stainless-304 or 305 2000° F Stainless-309 or 310 2500° F The temperatures indicated are those encountered in continuous service. Slightly higher temperatures can be withstood if the fluctuation is cyclic in nature. For applications above 2500° F, the anchors can be made of inconel or other special metals.

www.sunbeltstudwelding.com Sunbelt Stud Welding, Inc. 6381 Windfern Road Houston, Texas 77040-4915

11-2

1-800-462-9353 713-939-8903 fax 713-939-9013

ARC STUD WELDED REFRACTORY ANCHOR APPLICATION GUIDE (TABLE #2)

RA EJ-801

RA T-PLT

RA SP

RA Y

RA BH

RA UL

RA R-C

RA R-3T

RA R-2T

ARC R-TS

ARC R-WH

ARC B-NT

ARC ST

APPLICATION

RA EJ-256

REFRACTORY ANCHOR STYLE

a) Reinforcing Bar b) Wire Mesh c) Hex-Mesh Steel BLOCK INSULATION ONLY CONCRETE CONSTRUCTION a) Castables b) Plastics REFRACTORY c) Gunning Mixes CONSTRUCTION d) Block Insulation SINGLE a) Under 5” Thick COMPONENT b) Over 5” Thick a) Under 5” Thick b) Over 5” Thick TWO c) Brick Backing COMPONENT d) Castable Backing LININGS e) Block Insulation Backing REBAR & MESH

HOW TO APPLY THE REFRACTORY ANCHOR

ANCHOR LENGTH & SPACING: All information given in this section is general and may vary according to special service conditions encountered. Therefore, this information should only be used as a guide. The anchor length shown is the after-weld length of the longest section of the anchor. The lengths (in table #3) are recommended to insure good refractory holding power, while preventing rapid oxidation of the anchor and preventing spalling of the refractory surface. Generally the anchor length should be about 75% of the refractory depth, however, the end of the anchor should never be closer to the refractory hot face than 1”. The anchor spacing will be determined by the type and density of the refractory used, and how and where it is to be applied. For anchoring purposes, the refractory can be classified as LOW DENSITY (25-90 lbs. per cu. Ft.) and HIGH DENSITY (100-200 lbs. per cu. Ft.). High-density material can be used in one component linings of any thickness. Low-density material is only used in one component linings to a depth of 6”. Frequently, in sections more than 6” thick, high-density material composes the working lining with a back up of low-density material. www.sunbeltstudwelding.com Sunbelt Stud Welding, Inc. 6381 Windfern Road Houston, Texas 77040-4915

11-3

1-800-462-9353 713-939-8903 fax 713-939-9013

REFRACTORY ANCHOR PLACEMENT (TABLE #3)

Low High Low High Low High Low High Low High

CENTER – CENTER ANCHOR SPACING WALL ROOF 12” x 12” 9” x 9” 18” x 18” 12” x 12” 12” x 12” 12” x 12” 18” x 18” 18” x 18” 12” x 12” 12” x 12” 18” x 12” 18” x 12” 12” x 12” 12” x 9” 18” x 12” 18” x 12” 12” x 9” 9” x 9” 18” x 12” 12” x 12”

5”

High

18” x 12”

12” x 12”

8”

6”

High

18” x 12”

12” x 12”

9”

6-1/2”

High

18” x 12”

12” x 9”

10”

7-1/2”

High

12” x 12”

12” x 9”

11”

8”

High

12” x 12”

12” x 9”

12”

9”

High

12” x 12”

12” x 9”

13”

10”

High

12” x 12”

12” x 9”

REFRACTORY THICKNESS

ANCHOR LENGTH

2”

1”

3”

2”

4”

3”

5”

3-1/2”

6”

4-1/2”

7”

REFRACTORY DENSITY

QUANTITY OF ANCHORS REQUIRED (TABLE #4) ANCHOR SPACING ANCHORS REQ. PER SQ. FOOT

9” X 9”

12” X 9”

12” X 12”

18” X 12”

18” X 18”

1.80

1.33

1.00

0.67

0.44

www.sunbeltstudwelding.com Sunbelt Stud Welding, Inc. 6381 Windfern Road Houston, Texas 77040-4915

11-4

1-800-462-9353 713-939-8903 fax 713-939-9013

REFRACTORY ANCHORS: ANCHOR PATTERNS ANCHOR PATTERNS The three anchor patterns (shown below) are in use today; the latter two being the more popular. The important factor is that an irregular pattern is achieved by opposing anchors so that secure retention of the refractory in all directions is achieved.

NOTE: The expansion of the steel anchor is usually greater than that of the refractory material, especially in dense, high strength castables. Metallic refractory anchors can be coated with various materials that will burn off and allow room for the anchor to expand Consult your refractory supplier for the proper refractory and coating material to meet your application needs.

www.sunbeltstudwelding.com Sunbelt Stud Welding, Inc. 6381 Windfern Road Houston, Texas 77040-4915

11-5

1-800-462-9353 713-939-8903 fax 713-939-9013

REFRACTORY STUDS: RECTANGULAR TWO TINE

www.sunbeltstudwelding.com Sunbelt Stud Welding, Inc. 6381 Windfern Road Houston, Texas 77040-4915

11-6

1-800-462-9353 713-939-8903 fax 713-939-9013

REFRACTORY STUDS: RECTANGULAR THREE TINE

www.sunbeltstudwelding.com Sunbelt Stud Welding, Inc. 6381 Windfern Road Houston, Texas 77040-4915

11-7

1-800-462-9353 713-939-8903 fax 713-939-9013

REFRACTORY STUDS: RECTANGULAR CORRUGATED

www.sunbeltstudwelding.com Sunbelt Stud Welding, Inc. 6381 Windfern Road Houston, Texas 77040-4915

11-8

1-800-462-9353 713-939-8903 fax 713-939-9013

REFRACTORY WELD STUDS: INSULTWIST

Note: Washers are not a component part of studs.

www.sunbeltstudwelding.com Sunbelt Stud Welding, Inc. 6381 Windfern Road Houston, Texas 77040-4915

11-9

1-800-462-9353 713-939-8903 fax 713-939-9013

REFRACTORY STUDS: BULL HORN

www.sunbeltstudwelding.com Sunbelt Stud Welding, Inc. 6381 Windfern Road Houston, Texas 77040-4915

11-10

1-800-462-9353 713-939-8903 fax 713-939-9013

REFRACTORY STUDS: “Y” ANCHOR

www.sunbeltstudwelding.com Sunbelt Stud Welding, Inc. 6381 Windfern Road Houston, Texas 77040-4915

11-11

1-800-462-9353 713-939-8903 fax 713-939-9013

REFRACTORY STUDS: SPLIT PIN

www.sunbeltstudwelding.com Sunbelt Stud Welding, Inc. 6381 Windfern Road Houston, Texas 77040-4915

11-12

1-800-462-9353 713-939-8903 fax 713-939-9013

REFRACTORY STUDS: “T” PLATE

www.sunbeltstudwelding.com Sunbelt Stud Welding, Inc. 6381 Windfern Road Houston, Texas 77040-4915

11-13

1-800-462-9353 713-939-8903 fax 713-939-9013

REFRACTORY STUDS: KNURLED

www.sunbeltstudwelding.com Sunbelt Stud Welding, Inc. 6381 Windfern Road Houston, Texas 77040-4915

11-14

1-800-462-9353 713-939-8903 fax 713-939-9013

RECTANGULAR TWO TINE

RECTANGULAR THREE TINE

RECTANGULAR CORRUGATED

INSULTWIST

BULL HORN

“Y” ANCHOR

SPLIT PIN

“T” PLATE

KNURLED

*OTHER STUDS AVAILABLE ON REQUEST.

www.sunbeltstudwelding.com Sunbelt Stud Welding, Inc. 6381 Windfern Road Houston, Texas 77040-4915

11-1

1-800-462-9353 713-939-8903 fax 713-939-9013

GENERAL SPECIFICATIONS ARC STUD WELDED ANCHORS

MATERIAL: PLATING: ANNEALING: WELD BASE: STUD LENGTH:

FERRULES:

ARC STUD WELDED REFRACTORY ANCHORS Standard in low carbon steel and 302/304/305 stainless. Monel, inconel, and other grades of stainless steel are available. Plating is not standard. Cium to ASTM A 165, type TS and zinc to ASTM B 633 are available. Non-weldable plating is removed from the weld end to avoid contamination of the weld. Low carbon steel can be annealed to a maximum of 75 Rockwell B and stainless steel to a maximum of 90 Rockwell B. Solid flux is provided where required. SUNBELT arc stud length APPROX. STUD DIAMETER designations are BEFORE WELD. REDUCTION AFTER WELD lengths are shown in 3/16” thru 1/2” 1/8” the table. 5/8” thru 7/8” 3/16” 7/8” and over 1/4” 1/8” wide rectangulars 1/8” All orders include ferrules when they are required.

DEG WITH SUNBELT ARC STUD WELDED REFRACTORY ANCHORS: Advantages: SUNBELT arc stud welded refractory anchors reduce costs and downtime and increase production through speedier installation and improved product quality. Arc stud welding systems are portable and require minimal instruction or maintenance for use. Speed of anchor application and ease of use reduce labor requirements and eliminate other complicated fastening systems while maintaining excellent weld quality and improved refractory holding power.

HOW TO CHOOSE THE PROPER REFRACTORY ANCHOR STYLE: See table on 11-3 MATERIAL: The following temperature limits at the hot face or surface of the refractory, are recommended for anchors of the steel grades shown. STEEL TYPE HOT FACE TEMP. LIMIT Low Carbon Steel 1000° F Stainless-304 or 305 2000° F Stainless-309 or 310 2500° F The temperatures indicated are those encountered in continuous service. Slightly higher temperatures can be withstood if the fluctuation is cyclic in nature. For applications above 2500° F, the anchors can be made of inconel or other special metals.

www.sunbeltstudwelding.com Sunbelt Stud Welding, Inc. 6381 Windfern Road Houston, Texas 77040-4915

11-2

1-800-462-9353 713-939-8903 fax 713-939-9013

ARC STUD WELDED REFRACTORY ANCHOR APPLICATION GUIDE (TABLE #2)

RA EJ-801

RA T-PLT

RA SP

RA Y

RA BH

RA UL

RA R-C

RA R-3T

RA R-2T

ARC R-TS

ARC R-WH

ARC B-NT

ARC ST

APPLICATION

RA EJ-256

REFRACTORY ANCHOR STYLE

a) Reinforcing Bar b) Wire Mesh c) Hex-Mesh Steel BLOCK INSULATION ONLY CONCRETE CONSTRUCTION a) Castables b) Plastics REFRACTORY c) Gunning Mixes CONSTRUCTION d) Block Insulation SINGLE a) Under 5” Thick COMPONENT b) Over 5” Thick a) Under 5” Thick b) Over 5” Thick TWO c) Brick Backing COMPONENT d) Castable Backing LININGS e) Block Insulation Backing REBAR & MESH

HOW TO APPLY THE REFRACTORY ANCHOR

ANCHOR LENGTH & SPACING: All information given in this section is general and may vary according to special service conditions encountered. Therefore, this information should only be used as a guide. The anchor length shown is the after-weld length of the longest section of the anchor. The lengths (in table #3) are recommended to insure good refractory holding power, while preventing rapid oxidation of the anchor and preventing spalling of the refractory surface. Generally the anchor length should be about 75% of the refractory depth, however, the end of the anchor should never be closer to the refractory hot face than 1”. The anchor spacing will be determined by the type and density of the refractory used, and how and where it is to be applied. For anchoring purposes, the refractory can be classified as LOW DENSITY (25-90 lbs. per cu. Ft.) and HIGH DENSITY (100-200 lbs. per cu. Ft.). High-density material can be used in one component linings of any thickness. Low-density material is only used in one component linings to a depth of 6”. Frequently, in sections more than 6” thick, high-density material composes the working lining with a back up of low-density material. www.sunbeltstudwelding.com Sunbelt Stud Welding, Inc. 6381 Windfern Road Houston, Texas 77040-4915

11-3

1-800-462-9353 713-939-8903 fax 713-939-9013

REFRACTORY ANCHOR PLACEMENT (TABLE #3)

Low High Low High Low High Low High Low High

CENTER – CENTER ANCHOR SPACING WALL ROOF 12” x 12” 9” x 9” 18” x 18” 12” x 12” 12” x 12” 12” x 12” 18” x 18” 18” x 18” 12” x 12” 12” x 12” 18” x 12” 18” x 12” 12” x 12” 12” x 9” 18” x 12” 18” x 12” 12” x 9” 9” x 9” 18” x 12” 12” x 12”

5”

High

18” x 12”

12” x 12”

8”

6”

High

18” x 12”

12” x 12”

9”

6-1/2”

High

18” x 12”

12” x 9”

10”

7-1/2”

High

12” x 12”

12” x 9”

11”

8”

High

12” x 12”

12” x 9”

12”

9”

High

12” x 12”

12” x 9”

13”

10”

High

12” x 12”

12” x 9”

REFRACTORY THICKNESS

ANCHOR LENGTH

2”

1”

3”

2”

4”

3”

5”

3-1/2”

6”

4-1/2”

7”

REFRACTORY DENSITY

QUANTITY OF ANCHORS REQUIRED (TABLE #4) ANCHOR SPACING ANCHORS REQ. PER SQ. FOOT

9” X 9”

12” X 9”

12” X 12”

18” X 12”

18” X 18”

1.80

1.33

1.00

0.67

0.44

www.sunbeltstudwelding.com Sunbelt Stud Welding, Inc. 6381 Windfern Road Houston, Texas 77040-4915

11-4

1-800-462-9353 713-939-8903 fax 713-939-9013

REFRACTORY ANCHORS: ANCHOR PATTERNS ANCHOR PATTERNS The three anchor patterns (shown below) are in use today; the latter two being the more popular. The important factor is that an irregular pattern is achieved by opposing anchors so that secure retention of the refractory in all directions is achieved.

NOTE: The expansion of the steel anchor is usually greater than that of the refractory material, especially in dense, high strength castables. Metallic refractory anchors can be coated with various materials that will burn off and allow room for the anchor to expand Consult your refractory supplier for the proper refractory and coating material to meet your application needs.

www.sunbeltstudwelding.com Sunbelt Stud Welding, Inc. 6381 Windfern Road Houston, Texas 77040-4915

11-5

1-800-462-9353 713-939-8903 fax 713-939-9013

REFRACTORY STUDS: RECTANGULAR TWO TINE

www.sunbeltstudwelding.com Sunbelt Stud Welding, Inc. 6381 Windfern Road Houston, Texas 77040-4915

11-6

1-800-462-9353 713-939-8903 fax 713-939-9013

REFRACTORY STUDS: RECTANGULAR THREE TINE

www.sunbeltstudwelding.com Sunbelt Stud Welding, Inc. 6381 Windfern Road Houston, Texas 77040-4915

11-7

1-800-462-9353 713-939-8903 fax 713-939-9013

REFRACTORY STUDS: RECTANGULAR CORRUGATED

www.sunbeltstudwelding.com Sunbelt Stud Welding, Inc. 6381 Windfern Road Houston, Texas 77040-4915

11-8

1-800-462-9353 713-939-8903 fax 713-939-9013

REFRACTORY WELD STUDS: INSULTWIST

Note: Washers are not a component part of studs.

www.sunbeltstudwelding.com Sunbelt Stud Welding, Inc. 6381 Windfern Road Houston, Texas 77040-4915

11-9

1-800-462-9353 713-939-8903 fax 713-939-9013

REFRACTORY STUDS: BULL HORN

www.sunbeltstudwelding.com Sunbelt Stud Welding, Inc. 6381 Windfern Road Houston, Texas 77040-4915

11-10

1-800-462-9353 713-939-8903 fax 713-939-9013

REFRACTORY STUDS: “Y” ANCHOR

www.sunbeltstudwelding.com Sunbelt Stud Welding, Inc. 6381 Windfern Road Houston, Texas 77040-4915

11-11

1-800-462-9353 713-939-8903 fax 713-939-9013

REFRACTORY STUDS: SPLIT PIN

www.sunbeltstudwelding.com Sunbelt Stud Welding, Inc. 6381 Windfern Road Houston, Texas 77040-4915

11-12

1-800-462-9353 713-939-8903 fax 713-939-9013

REFRACTORY STUDS: “T” PLATE

www.sunbeltstudwelding.com Sunbelt Stud Welding, Inc. 6381 Windfern Road Houston, Texas 77040-4915

11-13

1-800-462-9353 713-939-8903 fax 713-939-9013

REFRACTORY STUDS: KNURLED

www.sunbeltstudwelding.com Sunbelt Stud Welding, Inc. 6381 Windfern Road Houston, Texas 77040-4915

11-14

1-800-462-9353 713-939-8903 fax 713-939-9013