Nelson Stud Catalog 5j6k5p

This document was ed by and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this report form. Report 445h4w

Overview 1s532p

& View Nelson Stud Catalog as PDF for free.

More details 6h715l

- Words: 39,364

- Pages: 110

2010 Nelson Stud Welding Stud and Ferrule Catalog About this catalog: This catalog is designed to be a -friendly source of online information about the Nelson Stud Welding line of studs, anchors, pins, and the standard accessories used to weld them. Many features have been incorporated into the pages of this catalog to enable you, the customer, to find the information you need quickly and easily. Many studs, pins, anchors, and ferrules are featured to provide the greatest range of possible solutions to your stud welding applications. Text explanations have been added to clarify some of the potential uses of each stud. Suggestions for similar use studs will assist you in making the correct stud choice for your stud welding application. PDF format creates a quicker ing, more informative catalog that is readable on both IBM and Macintosh platforms. Security features assure that the information you from our web site is genuine Nelson information. Links embedded in each page take you right to the information you need, making the stud information more easily accessible. Bookmarks have been added to make navigation through the catalog quick and easy. Detailed ferrule and accessory information allows you to identify and specify the exact parts you need to execute the job. Clickable table of contents and indexes quickly locates the stud information you need. Studs are indexed by welding process and use in industry to make finding the stud you need faster and easier. Company information is provided on every specification sheet to make communication with Nelson Stud Welding faster than ever before! We believe this is the easiest to use, most comprehensive catalog that Nelson Stud Welding has ever published. Your questions, comments, and suggestions are welcome and appreciated. Please follow the bookmark at left. Thank you for choosing to this catalog. We think you will find it the most useful and informative method to explore the Nelson Stud Welding product line.

Using the 2010 Nelson Stud Welding, Inc. Electronic Catalog Copyright

2004 Nelson Stud Welding, Inc. All rights reserved.

All information contained herein is the property of Nelson Stud Welding, Inc. and is intended for the use of our customers. This information pertains solely to Nelson studs and related accessories. Use of this information in conjunction with non-Nelson studs and related accessories is not recommended by Nelson Stud Welding, Inc. Nelson Stud Welding, Inc. assumes no financial or physical responsibility for damage or harm resulting from this information’s use with non-Nelson studs and related accessories. No part of this publication (whether in hard copy or electronic form) may be reproduced or transmitted, in any form or by any means, electronic, mechanical, photocopying, recording, or otherwise, without prior written consent of Nelson Stud Welding, Inc. Stored Arc and Tranquil Arc are ed trademarks of Nelson Stud Welding, Inc. All instances of the names Stored Arc or Tranquil Arc in the text are references to the Stored Arc stud welding process or Tranquil Arc accessory kit, as defined by Nelson Stud Welding, Inc., unless otherwise indicated. CrimpLok and Setlok are ed trademarks of Nelson Stud Welding, Inc. All instances of the names CrimpLok or Setlok in the text are references to the CrimpLok style of cable hangers or Setlok studs and caps, as defined by Nelson Stud Welding, Inc., unless otherwise indicated. The Nelson name, logos, and the Nelson eagle are all trademarks of Nelson Stud Welding, Inc. Adobe and Adobe Acrobat are trademarks of Adobe Systems Incorporated. All other trademarks or name brands are trademarks of their respective holders. This publication and the information herein is furnished AS IS, is subject to change without notice, and should not be construed as a commitment by Nelson Stud Welding, Inc. Nelson Stud Welding, Inc. assumes no responsibility or liability for any errors or inaccuracies, makes no warranty of any kind (express, implied, or statutory) with respect to this publication, and expressly disclaims any and all warranties of merchantability, fitness for particular purposes, and noninfringement of third party rights.

Version History 29 January 2004

First release as a catalog

New Features Make Using This Manual Easy!

Click on the Bookmarks to quickly locate the proper page.

Click on the red text or image here to view the standard stocked item numbers and descriptions on Nelson’s website

Click on the red text here to view Similar Studs.

Click on the red text here to go to the Material Specifications

Prominently located information allows you to quickly access Nelson Stud Welding. Red text indicates World Wide Web Links.

Table of Contents General Material Specifications Mild Steel and Stainless Steel ..................................................................................................................... Aluminum.....................................................................................................................................................

1 2

General Stud Specifications ............................................................................................................. 3 Stud Weld Studs Aluminum Studs CKA Aluminum Collar Stud.................................................................................................................. HBA Threaded Aluminum Stud............................................................................................................ N3A Aluminum Navy Type Annular Pin ............................................................................................... NBA No Thread Aluminum Stud .......................................................................................................... SBA Threaded Aluminum Shoulder Stud............................................................................................. TBA Internally Threaded Aluminum Stud.............................................................................................

11 12 13 14 15 16

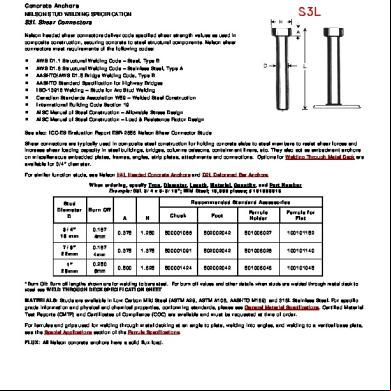

Cable Hangers Banding Style Cable Hanger ............................................................................................................... 17 CrimpLok™ Cable Hanger ................................................................................................................... 18 Concrete Anchors D2L Deformed Bar Anchor .................................................................................................................. 19 H4L Headed Concrete Anchor............................................................................................................. 20 S3L Shear Connector .......................................................................................................................... 21 High Strength.............................................................................................................................................. 22 Rectangular Studs R1P and R1L Rectangular Stud without Hole...................................................................................... R2P Rectangular Notched Stud........................................................................................................... R5P Strand Stud .................................................................................................................... R6P Rectangular Slotted Stud ............................................................................................................. R7P Rectangular Stud with Hole ......................................................................................................... R9L Rope Hook Stud........................................................................................................................... RWP Wiggley Two Tine Stud .............................................................................................................. RXX FiberLok™ Stud...........................................................................................................................

23 24 25 26 27 28 29 30

Refractory Anchors F3L Flanged Collar Stud...................................................................................................................... L2L Lagging Stud with Hole................................................................................................................. S4X “Y” Anchor Stud ........................................................................................................................... S7X Steerhorn Refractory Anchor Stud ...............................................................................................

31 32 33 34

Threaded Studs Internally Threaded PBL and TBL Internally Threaded Stud ........................................................................................ 35 S6L Sprinkler Stud........................................................................................................................ 36 Externally Threaded B5L 90° Bent Collar Stud.............................................................................................................. CFL Fully Threaded Stud ............................................................................................................. CFP, FFP, P, and FPP Small Diameter Threaded Stud .......................................................... CJL Reduced Base Stud .............................................................................................................. CKL Collar Stud............................................................................................................................ L Partially Threaded Stud ........................................................................................................ HBL Full Base Diameter Threaded Stud ...................................................................................... SBL Shoulder Stud ....................................................................................................................... Watertight Nut...............................................................................................................................

37 38 39 40 41 42 43 44 45

Unthreaded Studs B4L and B4P Reinforcing Standoff Stud.............................................................................................. E2L “Eyebolt” Stud............................................................................................................................... J2L “J” Bolt Stud .................................................................................................................................. NBL No Thread Stud ........................................................................................................................... NJL Reduced Base Unthreaded Stud.................................................................................................. S2L Setlok Stud ................................................................................................................................... XBL and XXL Round Corner Square studs..........................................................................................

46 47 48 49 50 51 52

Short Cycle, Gas Arc, and Store Arc studs Automotive Studs AXC “Fir Tree” Stud ............................................................................................................................. Grounding Stud.................................................................................................................................... H8X “T” Stud........................................................................................................................................ “W” Top Wide Flange Stud ..................................................................................................................

53 54 55 56

Stored Arc ANC, ANS, and ANA Unthreaded Stored Arc® Stud........................................................................... 57 ATC, ATS, and ATA Threaded Stored Arc® Stud ............................................................................... 58

Capacitor Discharge (CD) TATC, TATS, and TATA Threaded Capacitor Discharge Stud ................................................................... TFNC, TFNS, and TFNA Flanged Unthreaded Capacitor Discharge Stud ................................................. TFTC, TFTS, and TFTA Flanged Threaded Capacitor Discharge Stud ...................................................... TUTC, TUTS, and TUTA Unflanged Threaded Capacitor Discharge Stud .................................................

59 60 61 62

Insulation Pins CHP Cupped Headed Insulation Pin........................................................................................................... N3P Navy Type Annular Ring Insulation Pin............................................................................................... P2P Double Pointed Insulation Pin ............................................................................................................. TPC, TPS, and TPA Single Pointed Insulation Pin .....................................................................................

63 64 65 66

Metric Studs ANC, ANS, and ANA Unthreaded Stored Arc® Stud.................................................................................. ATC, ATS, and ATA Threaded Stored Arc® Stud ...................................................................................... CKL Collar Stud .......................................................................................................................................... MD Fully Threaded Stud ............................................................................................................................. MR Reduced Base Stud ............................................................................................................................. MP Partially Threaded Stud ........................................................................................................................ MPF Partially Threaded Stud...................................................................................................................... NBL Unthreaded Stud................................................................................................................................. TBL Internally Threaded Stud ..................................................................................................................... TFNC, TFNS, TFNA Flanged Unthreaded Capacitor Discharge Stud ........................................................ TFTC, TFTS, TFTA Flanged Threaded Capacitor Discharge Stud.............................................................

67 68 69 70 71 72 73 74 75 76 77

Ferrules Standard Ferrules ....................................................................................................................................... Aluminum Ferrules...................................................................................................................................... Special Applications of Ferrules.................................................................................................................. Angle Welding ..................................................................................................................................... Curved Surface Welding...................................................................................................................... Edge Welding ...................................................................................................................................... Welding Into Fillets and Onto Heels..................................................................................................... Stripping Straight Off Headed Studs.................................................................................................... Vertical Surface Welding ..................................................................................................................... Welding Through Metal Decking.......................................................................................................... Rectangular Ferrules .................................................................................................................................. Reduced Base Ferrules .............................................................................................................................. Refractory Anchor Ferrules.........................................................................................................................

78 79 80 81 82 83 84 85 86 87 88 89 90

Accessories Chucks Stud Weld Chucks Standard Length Chucks .............................................................................................................. Long Length Chucks..................................................................................................................... Male Style Chucks and Adapters.................................................................................................. Rectangular Chucks ..................................................................................................................... 90° Bent Chucks........................................................................................................................... 45° Bent Chucks........................................................................................................................... Square Chucks ............................................................................................................................. Eyebolt Chucks............................................................................................................................. Side Gripping Chucks...................................................................................................................

91 92 93 94 95 96 97 98 99

Capacitor Discharge Chucks NCD-60, NCD-100, and NCD-150 Chucks and Stop Pins............................................................ CD-Lite-C and CD-Lite-G Chucks................................................................................................. Feet............................................................................................................................................................. Ferrule Grips and Ferrule Holders ..............................................................................................................

100 101 102 103

Index................................................................................................................................................... I1

General Information for Stud Welding Studs Material Specifications Nelson’s studs may be made of one of the following materials, as specified on individual specification sheets. Certificates of chemical analysis and physical properties are available, upon request. All physical and chemical properties are independent of stud size or shape. Mild Steel Standard mild steel studs manufactured by Nelson conform to ASTM A –108 specifications for 1010 through 1020 mild steels. Physical properties and chemical composition of mild steel Nelson studs are in accordance with AWS D1.1. Special studs can also be manufactured of other weldable mild steels. Heat treatments and plating can be applied to mild steel studs, upon request. Mild Steel Chemical Composition Element

Minimum wt%

Maximum wt%

C Mn P S

0.08 0.30 ---

0.23 0.90 0.04 0.05

Stainless Steel Standard Nelson studs manufactured of stainless steel conform to ASTM A –276 or A –493 specifications. Studs can be manufactured from other weldable stainless steel alloys. Mechanical properties of Nelson stainless steel studs depend on the cold working or heat treatment applied to the studs after forming. Stainless steel studs can be annealed, upon request. Stainless Steel Chemical Composition Element C Cr Ni Mn Cu

302HQ (30430) All other studs

316L (31603) Shear and Concrete Anchors

Minimum wt%

Maximum wt%

Minimum wt%

Maximum wt%

-17.00 8.00 -3.00

0.12 20.00 13.00 2.00 4.00

-16.00 10.00 ---

0.03 18.00 14.00 2.00 --

Mechanical Properties - Standard Minimum Values Yield, 0.2% offset (psi), Re Ultimate Tensile (psi), Rm % Elongation, A5, in 2” gage length % Area Reduction

Mild Steel Shear and Concrete Anchors 51,000 65,000 20 N/A

Standard Mild Steel Studs

Mild Steel Deformed Bar Anchors

Stainless Steel Studs, as formed

Stainless Steel Studs, as formed, post-annealed

49,000 61,000 17 N/A

70,000 80,000 N/A N/A

50,000 75,000 40 50

30,000 70,000 40 50

Mechanical Properties - Metric Minimum Values Yield, 0.2% offset (MPa), Re Ultimate Tensile (MPa), Rm % Elongation, A5, in 5 x diameter % Area Reduction

Mild Steel Shear and Concrete Anchors 350 450 20 N/A

Standard Mild Steel Studs

Mild Steel Deformed Bar Anchors

Stainless Steel Studs, as formed

Stainless Steel Studs, as formed, post-annealed

340 420 17 N/A

485 552 N/A N/A

345 517 40 50

206 483 40 50

General Information for Stud Welding Studs Aluminum Nelson manufactured aluminum studs are made from Aluminum Association (AA) alloys 5356, 6061, or 1100. Aluminum studs can be annealed upon request. The chemical composition and physical propertied of these alloys are shown below. Aluminum Alloy Chemical Composition Alloy 1100

Element Al Cr Cu Mn Si Fe Si + Fe Zn Mg Ti

Alloy 5356

Alloy 6061

Minimum wt%

Maximum wt%

Minimum wt%

Maximum wt%

Minimum wt%

Maximum wt%

99 -0.05 -N/A N/A -----

--0.2 0.05 N/A N/A 0.95 0.1 ---

94.6 0.05 -0.05 --N/A -4.5 0.06

94.6 0.2 0.1 0.2 0.25 0.4 N/A 0.1 5.5 0.2

98 0.04 0.15 -0.4 -N/A -0.8 --

98 0.35 0.4 0.15 0.8 0.7 N/A 0.25 1.2 0.15

Mechanical Properties - Standard Minimum Values

1100 H-16

5356 H-32

6061- T-6

Yield, 0.2% offset (psi), Re Ultimate Tensile (psi), Rm % Elongation, A5, 0.2% at 2” gage length % Area Reduction

20,000 21,000 17 N/A

32,000 46,000 24 N/A

40,000 45,000 17 N/A

Mechanical Properties - Metric Minimum Values

1100 H-16

5356 H-32

6061- T-6

Yield, 0.2% offset (MPa), Re Ultimate Tensile (MPa), Rm % Elongation, A5, 0.2% at 2” gage length % Area Reduction

138 145 17 N/A

221 317 24 N/A

276 310 17 N/A

NELSON STUD WELDING MANUFACTURING SPECIFICATION: Cold Formed Parts The primary method used by Nelson to produce stud welded fasteners is the Cold Forming process. Utilizing the same cold heading production equipment, Nelson produces an extensive line of nonwelded, cold-formed parts. These parts can be custom designed to satisfy the specific requirements of individual to a particular customers. Pictured at right are just some of the many different cold-formed parts and shapes that Nelson is capable of producing. If you are currently purchasing cold-formed or screw-machined parts, Nelson may be able to offer cost savings and quality improvements. To understand Nelson’s capabilities and to determine if cold forming will benefit you, consult the following specification.

Should You Inquire about Nelson’s Cold Forming Capability? The answer is YES if: • • • • • • • •

Your part is 1” or less in diameter, and the shank diameter is 1” or less, and the length does is less than 15”. Your part is assembled from several components. Your annual part volume is 100,000 pieces or more. You currently experience substantial material waste. You require closer tolerances. You need greater process control capability (higher K). You desire greater part strength and/or better surface finish is desired. You have not shopped your part cost in several years.

You should submit the following information for a FREE Cost Quotation:

Nelson’s Capabilities:

• • • •

• • •

Wire diameter ranging from 1/8” (0.125”) through 1”. Upset forming diameters up to 225% of wire diameter. Cut-off length up to 15”. Up to five dies and hammers can be used to progressively form complex shapes.

• • • •

Part drawing with critical dimensions. Order quantity and annual volume. A sample of the part you are currently purchasing. Your target pricing.

Upsets, forward and backward extrusions, punched and through holes, flanges, collars, heads, and other forming techniques can be accommodated Production rates from 45 to 450 pieces per minute. Complete secondary operations. In-house tool and die design and fabrication.

Visit our website www.NelsonStudWelding.com for a list of our standard stock products. Nelson Stud Welding, Inc. 7900 West Ridge Road Elyria, Ohio 44035

PH 1-800-NEL-WELD 1-800-635-9353

E-mail: [email protected]

1/04

General Information for Stud Welding Studs Standard Arc Welding Studs – Tensile and Torque Strengths Mild Steel – 61,000psi Minimum Ultimate, 50,000 psi Minimum Yield 2

3

Ultimate Torque (ft-lbs) at 61,000 psi 3.3 3.8

Shear Strength (75% of Tensile Strength) 796 915

10-24 UNC 10-32 UNF

0.0174 0.0199

Yield Load (lbs.) at 50,000 psi 870 1,000

1/4-20 UNC 1/4-28 UNF

0.0317 0.0362

1,590 1,810

1,940 2,208

6.6 7.5

8.1 9.2

1,455 1,656

5/16-18 UNC 5/16-24 UNF

0.0522 0.0579

2,620 2,895

3,196 3,532

13.6 15.1

16.6 18.4

2,397 2,649

3/8-16 INC 3/8-24 UNF

0.0773 0.0876

3,875 4,380

4,728 5,344

24.2 27.4

29.5 33.4

3,546 4,008

7/16- 14 UNC 7/16-20 UNF

0.1060 0.1185

5,315 5,900

6,484 7,198

38.7 43.0

47.2 52.4

4,863 5,399

1/2-13 UNC 1/2-20 UNF

0.1416 0.1597

7,095 8,000

8,656 9,760

59.1 66.7

72.1 81.3

6,492 7,320

5/8-11 UNC 5/8-18 UNF

0.2256 0.2555

11,300 12,750

13,786 15,555

117.7 132.8

143.6 162.0

10,340 11,666

3/4-10 INC 3/4-16 UNF

0.3340 0.3724

16,700 18,600

20,374 22,692

208.8 232.5

254.7 283.7

15,281 17,019

7/8-9 UNC 7/8-14 UNF

0.4612 0.5088

23,100 25,450

28,182 31,049

336.9 371.1

411.0 452.8

21,137 23,287

Thread Diameter

1

META (sq. in.)

Ultimate Tensile Load (lbs) at 61,000 psi 1,061 1,220

Yield Torque (ft-lbs) at 50,000 psi 2.7 3.1

1-8 UNC 0.6051 30,300 36,966 505.0 616.1 27,725 1-14 UNF 0.6791 33,900 41,358 565.0 689.3 31,019 * Torque figures based on assumption that excessive deformation of thread has not taken relationship between torque/tension out of its proportional range.

In actual practice, stud should not be used at its yield load. A factor of safety must be applied. It is generally recommended that studs not be used at more than 60% of yield strength, however, the factor of safety may vary up or down according to the particular application in which the studs are being used. The of these studs will make this determination Formulae used to make the above calculations are as follows: Ultimate Tensile L = SA Ultimate Torque Yield Z = YA Yield Torque Where

T = 0.2 x D x L T = 0.2 x D x Z

D = Nominal Thread Diameter A = Mean Effective Thread Area (META) S = Tensile Stress (psi) Y = Yield Stress (psi) L = Tensile Load (lbs) Z = Yield Load T = Torque (in-lbs)

1

META is used instead of root area in calculating screw lengths because of closer correlation with actual tensile strength. META is based on mean diameter, which is the diameter of an imaginary co-axial cylinder whose surface would through the thread profile approximately midway between the minor and pitch diameters.

2

In actual practice, stud should not be used at its yield load. A factor of safety must be applied. It is generally recommended that studs not be used at more than 60% of yield strength, however, the factor of safety may vary up or down according to the particular application in which the studs are being used. The will make this safety factor determination

3 Shear values are based on Tensile Strength of the stud.

General Information for Stud Welding Studs Stainless Steel (Post Annealed) – 70,000psi Minimum Ultimate, 30,000 psi Minimum Yield 2

3

Ultimate Torque (ft-lbs) at 70,000 psi 3.8 4.4

Shear Strength (75% of Tensile Strength) 913 1,045

10-24 UNC 10-32 UNF

0.0174 0.0199

Yield Load (lbs.) at 30,000 psi 522 600

1/4-20 UNC 1/4-28 UNF

0.0317 0.0362

954 1,086

2,219 2,534

4.0 4.5

9.2 10.5

1,664 1,900

5/16-18 UNC 5/16-24 UNF

0.0522 0.0579

1,572 1,737

3,654 4,053

8.2 9.0

19.0 21.1

2,740 3,040

3/8-16 INC 3/8-24 UNF

0.0773 0.0876

2,325 2,628

5,411 6,132

14.5 16.4

33.9 38.4

4,058 4,599

7/16- 14 UNC 7/16-20 UNF

0.1060 0.1185

3,189 3,540

7,420 8,295

23.2 25.8

54.2 60.2

5,565 6,221

1/2-13 UNC 1/2-20 UNF

0.1416 0.1597

4,257 4,800

9,912 11,179

35.5 40.0

82.8 93.3

7,434 8,384

5/8-11 UNC 5/8-18 UNF

0.2256 0.2555

6,780 7,650

15,795 17,885

70.6 79.7

164.8 185.9

11,846 13,414

3/4-10 INC 3/4-16 UNF

0.3340 0.3724

10,020 11,160

23,380 26,068

125.3 139.5

292.2 325.5

17,535 19,551

7/8-9 UNC 7/8-14 UNF

0.4612 0.5088

13,860 15,270

32,284 35,616

202.1 222.7

471.6 519.6

24,213 26,712

Thread Diameter

1

META (sq. in.)

Ultimate Tensile Load (lbs) at 70,000 psi 1,218 1,393

Yield Torque (ft-lbs) at 30,000 psi 1.6 1.9

1-8 UNC 0.6051 18,180 42,357 303.0 707.0 31,768 1-14 UNF 0.6791 20,340 47,537 339.0 791.0 35,653 * Torque figures based on assumption that excessive deformation of thread has not taken relationship between torque/tension out of its proportional range.

In actual practice, stud should not be used at its yield load. A factor of safety must be applied. It is generally recommended that studs not be used at more than 60% of yield strength, however, the factor of safety may vary up or down according to the particular application in which the studs are being used. The of these studs will make this determination Formulae used to make the above calculations are as follows: Ultimate Tensile L = SA Ultimate Torque Yield Z = YA Yield Torque Where

T = 0.2 x D x L T = 0.2 x D x Z

D = Nominal Thread Diameter A = Mean Effective Thread Area (META) S = Tensile Stress (psi) Y = Yield Stress (psi) L = Tensile Load (lbs) Z = Yield Load T = Torque (in-lbs)

1

META is used instead of root area in calculating screw lengths because of closer correlation with actual tensile strength. META is based on mean diameter, which is the diameter of an imaginary co-axial cylinder whose surface would through the thread profile approximately midway between the minor and pitch diameters.

2

In actual practice, stud should not be used at its yield load. A factor of safety must be applied. It is generally recommended that studs not be used at more than 60% of yield strength, however, the factor of safety may vary up or down according to the particular application in which the studs are being used. The will make this safety factor determination

3 Shear values are based on Tensile Strength of the stud.

General Information for Stud Welding Studs Standard Arc Welding Studs – Tensile and Torque Strengths High Strength Steel – 115,000 psi Minimum Ultimate, 105,000 psi Minimum Yield Ultimate Tensile Yield Torque2 Shear Strength3 Load (lbs) at (ft-lbs) at (75% of Tensile 115,000 psi 105,000 psi Strength) M8 (0.315” dia.) 0.0567 5,954 6,521 23 4,890 M10 (0.394” dia.) 0.0899 9,440 10,399 46 7,754 M12 (0.472” dia.) 0.1306 13,713 15,019 81 11,318 5/16-18 0.0522 5,481 6003 25 4,485 3/8-16 0.0773 8,116 8895 38 6,727 1/2-13 0.1417 14,879 16296 93 15,975 Torque figures based on assumption that excessive deformation of thread has not taken relationship between torque/tension out of its proportional range. Thread Diameter

*

META1 (sq. in.)

Yield Load (lbs.) at 105,000 psi

In actual practice, stud should not be used at its yield load. A factor of safety must be applied. It is generally recommended that studs not be used at more than 60% of yield strength, however, the factor of safety may vary up or down according to the particular application in which the studs are being used. The of these studs will make this determination Formulae used to make the above calculations are as follows: Ultimate Tensile L = SA Ultimate Torque Yield Z = YA Yield Torque Where

T = 0.15 x D x L T = 0.15 x D x Z

D = Nominal Thread Diameter A = Mean Effective Thread Area (META) S = Tensile Stress (psi) Y = Yield Stress (psi) L = Tensile Load (lbs) Z = Yield Load T = Torque (in-lbs)

1

META is used instead of root area in calculating screw lengths because of closer correlation with actual tensile strength. META is based on mean diameter, which is the diameter of an imaginary co-axial cylinder whose surface would through the thread profile approximately midway between the minor and pitch diameters.

2

In actual practice, stud should not be used at its yield load. A factor of safety must be applied. It is generally recommended that studs not be used at more than 60% of yield strength, however, the factor of safety may vary up or down according to the particular application in which the studs are being used. The will make this safety factor determination

3 Shear values are based on Tensile Strength of the stud.

Stored Arc Welding Studs – Tensile/Yield Strengths Mild Steel – 61,000 psi Ultimate, 50,000 psi Yield Stainless Steel – 75,000psi Minimum Ultimate, 30,000 psi Minimum Yield Aluminum – 21,000 psi Ultimate, 20,000 psi Yield Thread Diameter 6-32 UNC 8-32 UNC 10-24 UNC 10-32 UNF 1/4-20 UNC 1/4-28 UNF

Ultimate Tensile Load (lbs)

Yield Load (lbs)

Mild Steel

Stainless Steel

Aluminum

Mild Steel

Stainless Steel

Aluminum

458 705 870 1,005 1,585 1,810

687 1,057 1,305 1,507 2,377 2,715

192 296 365 422 666 760

321 493 609 704 1,110 1,267

275 423 522 603 951 1,086

183 282 348 402 634 724

General Information for Stud Welding Studs Aluminum Nelson manufactured aluminum studs are made from Aluminum Association (AA) alloys 5356, 6061, or 1100. Aluminum studs can be annealed upon request. The chemical composition and physical propertied of these alloys are shown below. Aluminum Alloy Chemical Composition Alloy 1100

Element Al Cr Cu Mn Si Fe Si + Fe Zn Mg Ti

Alloy 5356

Alloy 6061

Minimum wt%

Maximum wt%

Minimum wt%

Maximum wt%

Minimum wt%

Maximum wt%

99 -0.05 -N/A N/A -----

--0.2 0.05 N/A N/A 0.95 0.1 ---

94.6 0.05 -0.05 --N/A -4.5 0.06

94.6 0.2 0.1 0.2 0.25 0.4 N/A 0.1 5.5 0.2

98 0.04 0.15 -0.4 -N/A -0.8 --

98 0.35 0.4 0.15 0.8 0.7 N/A 0.25 1.2 0.15

Mechanical Properties - Standard Minimum Values Yield, 0.2% offset (psi), Re Ultimate Tensile (psi), Rm % Elongation, A5, in 2” gage length % Area Reduction

1100 H-16

5356 H-32

6061- T-6

20,000 21,000 17 N/A

32,000 46,000 24 N/A

40,000 45,000 17 N/A

1100 H-16

5356 H-32

6061- T-6

138 145

221 317

276 310

Mechanical Properties - Metric Minimum Values Yield, 0.2% offset (MPa), Re Ultimate Tensile (MPa), Rm

General Information for Stud Welding Studs Standard Arc Welding Studs – Tensile and Torque Strengths Mild Steel – 61,000psi Minimum Ultimate, 50,000 psi Minimum Yield 2

3

Ultimate Torque (ft-lbs) at 61,000 psi 3.3 3.8

Shear Strength (75% of Tensile Strength) 796 915

10-24 UNC 10-32 UNF

0.0174 0.0199

Yield Load (lbs.) at 50,000 psi 870 1,000

1/4-20 UNC 1/4-28 UNF

0.0317 0.0362

1,590 1,810

1,940 2,208

6.6 7.5

8.1 9.2

1,455 1,656

5/16-18 UNC 5/16-24 UNF

0.0522 0.0579

2,620 2,895

3,196 3,532

13.6 15.1

16.6 18.4

2,397 2,649

3/8-16UNC 3/8-24 UNF

0.0773 0.0876

3,875 4,380

4,728 5,344

24.2 27.4

29.5 33.4

3,546 4,008

7/16- 14 UNC 7/16-20 UNF

0.1060 0.1185

5,315 5,900

6,484 7,198

38.7 43.0

47.2 52.4

4,863 5,399

1/2-13 UNC 1/2-20 UNF

0.1416 0.1597

7,095 8,000

8,656 9,760

59.1 66.7

72.1 81.3

6,492 7,320

5/8-11 UNC 5/8-18 UNF

0.2256 0.2555

11,300 12,750

13,786 15,555

117.7 132.8

143.6 162.0

10,340 11,666

3/4-10 UNC 3/4-16 UNF

0.3340 0.3724

16,700 18,600

20,374 22,692

208.8 232.5

254.7 283.7

15,281 17,019

7/8-9 UNC 7/8-14 UNF

0.4612 0.5088

23,100 25,450

28,182 31,049

336.9 371.1

411.0 452.8

21,137 23,287

Thread Diameter

1

META (sq. in.)

Ultimate Tensile Load (lbs) at 61,000 psi 1,061 1,220

Yield Torque (ft-lbs) at 50,000 psi 2.7 3.1

1-8 UNC 0.6051 30,300 36,966 505.0 616.1 27,725 1-14 UNF 0.6791 33,900 41,358 565.0 689.3 31,019 * Torque figures based on assumption that excessive deformation of thread has not taken relationship between torque/tension out of its proportional range.

In actual practice, stud should not be used at its yield load. A factor of safety must be applied. It is generally recommended that studs not be used at more than 60% of yield strength, however, the factor of safety may vary up or down according to the particular application in which the studs are being used. The of these studs will make this determination Formulae used to make the above calculations are as follows: Ultimate Tensile L = SA Ultimate Torque Yield Z = YA Yield Torque Where

T = 0.2 x D x L T = 0.2 x D x Z

D = Nominal Thread Diameter A = Mean Effective Thread Area (META) S = Tensile Stress (psi) Y = Yield Stress (psi) L = Tensile Load (lbs) Z = Yield Load T = Torque (in-lbs)

1

META is used instead of root area in calculating screw lengths because of closer correlation with actual tensile strength. META is based on mean diameter, which is the diameter of an imaginary co-axial cylinder whose surface would through the thread profile approximately midway between the minor and pitch diameters.

2

In actual practice, stud should not be used at its yield load. A factor of safety must be applied. It is generally recommended that studs not be used at more than 60% of yield strength, however, the factor of safety may vary up or down according to the particular application in which the studs are being used. The will make this safety factor determination

3 Shear values are based on Tensile Strength of the stud.

General Information for Stud Welding Studs Stainless Steel (Post Annealed) – 70,000psi Minimum Ultimate, 30,000 psi Minimum Yield 2

3

Ultimate Torque (ft-lbs) at 70,000 psi 3.8 4.4

Shear Strength (75% of Tensile Strength) 913 1,045

10-24 UNC 10-32 UNF

0.0174 0.0199

Yield Load (lbs.) at 30,000 psi 522 600

1/4-20 UNC 1/4-28 UNF

0.0317 0.0362

954 1,086

2,219 2,534

4.0 4.5

9.2 10.5

1,664 1,900

5/16-18 UNC 5/16-24 UNF

0.0522 0.0579

1,572 1,737

3,654 4,053

8.2 9.0

19.0 21.1

2,740 3,040

3/8-16 UNC 3/8-24 UNF

0.0773 0.0876

2,325 2,628

5,411 6,132

14.5 16.4

33.9 38.4

4,058 4,599

7/16- 14 UNC 7/16-20 UNF

0.1060 0.1185

3,189 3,540

7,420 8,295

23.2 25.8

54.2 60.2

5,565 6,221

1/2-13 UNC 1/2-20 UNF

0.1416 0.1597

4,257 4,800

9,912 11,179

35.5 40.0

82.8 93.3

7,434 8,384

5/8-11 UNC 5/8-18 UNF

0.2256 0.2555

6,780 7,650

15,795 17,885

70.6 79.7

164.8 185.9

11,846 13,414

3/4-10 UNC 3/4-16 UNF

0.3340 0.3724

10,020 11,160

23,380 26,068

125.3 139.5

292.2 325.5

17,535 19,551

7/8-9 UNC 7/8-14 UNF

0.4612 0.5088

13,860 15,270

32,284 35,616

202.1 222.7

471.6 519.6

24,213 26,712

Thread Diameter

1

META (sq. in.)

Ultimate Tensile Load (lbs) at 70,000 psi 1,218 1,393

Yield Torque (ft-lbs) at 30,000 psi 1.6 1.9

1-8 UNC 0.6051 18,180 42,357 303.0 707.0 31,768 1-14 UNF 0.6791 20,340 47,537 339.0 791.0 35,653 * Torque figures based on assumption that excessive deformation of thread has not taken relationship between torque/tension out of its proportional range.

In actual practice, stud should not be used at its yield load. A factor of safety must be applied. It is generally recommended that studs not be used at more than 60% of yield strength, however, the factor of safety may vary up or down according to the particular application in which the studs are being used. The of these studs will make this determination Formulae used to make the above calculations are as follows: Ultimate Tensile L = SA Ultimate Torque Yield Z = YA Yield Torque Where

T = 0.2 x D x L T = 0.2 x D x Z

D = Nominal Thread Diameter A = Mean Effective Thread Area (META) S = Tensile Stress (psi) Y = Yield Stress (psi) L = Tensile Load (lbs) Z = Yield Load T = Torque (in-lbs)

1

META is used instead of root area in calculating screw lengths because of closer correlation with actual tensile strength. META is based on mean diameter, which is the diameter of an imaginary co-axial cylinder whose surface would through the thread profile approximately midway between the minor and pitch diameters.

2

In actual practice, stud should not be used at its yield load. A factor of safety must be applied. It is generally recommended that studs not be used at more than 60% of yield strength, however, the factor of safety may vary up or down according to the particular application in which the studs are being used. The will make this safety factor determination

3 Shear values are based on Tensile Strength of the stud.

General Information for Stud Welding Studs Stainless Steel (As Formed)) – 75,000psi Minimum Ultimate, 50,000 psi Minimum Yield 2

3

10-24 UNC 10-32 UNF

0.0174 0.0199

Yield Load (lbs.) at 50,000 psi 870 1,000

1/4-20 UNC 1/4-28 UNF

0.0317 0.0362

1,590 1,810

2,378 2,715

5.8 6.8

9.9 11.3

1,789 2,036

5/16-18 UNC 5/16-24 UNF

0.0522 0.0579

2,620 2,895

3,930 4,343

12.1 13.8

20.4 22.6

2,948 3,257

3/8-16 UNC 3/8-24 UNF

0.0773 0.0876

3,875 4,380

5,813 6,570

21.6 25.4

36.3 41.1

4,359 4,928

7/16- 14 UNC 7/16-20 UNF

0.1060 0.1185

5,315 5,900

7,973 8,850

34.6 39.8

58.1 64.5

5,979 6,638

1/2-13 UNC 1/2-20 UNF

0.1416 0.1597

7,095 8,000

10,643 12,000

53.2 62.3

88.7 100.0

7,982 9,000

5/8-11 UNC 5/8-18 UNF

0.2256 0.2555

11,300 12,750

16,950 19,125

106.6 125.1

176.6 199.2

12,713 14,344

3/4-10 UNC 3/4-16 UNF

0.3340 0.3724

16,700 18,600

25,050 27,900

190.7 219.9

313.1 348.8

18,788 20,925

7/8-9 UNC 7/8-14 UNF

0.4612 0.5088

23,100 25,450

34,650 38,175

309.1 351.5

505.3 556.7

25,998 28,631

Thread Diameter

1

META (sq. in.)

Ultimate Tensile Load (lbs) at 75,000 psi 1,305 1,500

Yield Torque (ft-lbs) at 50,000 psi 2.4 2.8

Ultimate Torque (ft-lbs) at 75,000 psi 4.1 4.7

Shear Strength (75% of Tensile Strength) 979 1,125

1-8 UNC 0.6051 30,300 45,450 464.0 757.5 34,088 1-14 UNF 0.6791 33,900 50,850 534.4 847.5 38,138 * Torque figures based on assumption that excessive deformation of thread has not taken relationship between torque/tension out of its proportional range.

In actual practice, stud should not be used at its yield load. A factor of safety must be applied. It is generally recommended that studs not be used at more than 60% of yield strength, however, the factor of safety may vary up or down according to the particular application in which the studs are being used. The of these studs will make this determination Formulae used to make the above calculations are as follows: Ultimate Tensile L = SA Ultimate Torque Yield Z = YA Yield Torque Where

T = 0.2 x D x L T = 0.2 x D x Z

D = Nominal Thread Diameter A = Mean Effective Thread Area (META) S = Tensile Stress (psi) Y = Yield Stress (psi) L = Tensile Load (lbs) Z = Yield Load T = Torque (in-lbs)

1

META is used instead of root area in calculating screw lengths because of closer correlation with actual tensile strength. META is based on mean diameter, which is the diameter of an imaginary co-axial cylinder whose surface would through the thread profile approximately midway between the minor and pitch diameters.

2

In actual practice, stud should not be used at its yield load. A factor of safety must be applied. It is generally recommended that studs not be used at more than 60% of yield strength, however, the factor of safety may vary up or down according to the particular application in which the studs are being used. The will make this safety factor determination

3 Shear values are based on Tensile Strength of the stud.

General Information for Stud Welding Studs Standard Arc Welding Studs – Tensile and Torque Strengths High Strength Steel – 115,000 psi Minimum Ultimate, 105,000 psi Minimum Yield Shear Strength3 Ultimate Tensile Yield Torque2 (ft-lbs) at (75% of Tensile Load (lbs) at 105,000 psi Strength) 115,000 psi M8 (0.315” dia.) 0.0567 5,954 6,521 23 4,890 M10 (0.394” dia.) 0.0899 9,440 10,399 46 7,754 M12 (0.472” dia.) 0.1306 13,713 15,019 81 11,318 5/16-18 0.0522 5,481 6003 25 4,485 3/8-16 0.0773 8,116 8895 38 6,727 1/2-13 0.1417 14,879 16296 93 15,975 Torque figures based on assumption that excessive deformation of thread has not taken relationship between torque/tension out of its proportional range. Thread Diameter

*

META1 (sq. in.)

Yield Load (lbs.) at 105,000 psi

In actual practice, stud should not be used at its yield load. A factor of safety must be applied. It is generally recommended that studs not be used at more than 60% of yield strength, however, the factor of safety may vary up or down according to the particular application in which the studs are being used. The of these studs will make this determination Formulae used to make the above calculations are as follows: Ultimate Tensile L = SA Ultimate Torque Yield Z = YA Yield Torque Where

T = 0.15 x D x L T = 0.15 x D x Z

D = Nominal Thread Diameter A = Mean Effective Thread Area (META) S = Tensile Stress (psi) Y = Yield Stress (psi) L = Tensile Load (lbs) Z = Yield Load T = Torque (in-lbs)

1

META is used instead of root area in calculating screw lengths because of closer correlation with actual tensile strength. META is based on mean diameter, which is the diameter of an imaginary co-axial cylinder whose surface would through the thread profile approximately midway between the minor and pitch diameters.

2

In actual practice, stud should not be used at its yield load. A factor of safety must be applied. It is generally recommended that studs not be used at more than 60% of yield strength, however, the factor of safety may vary up or down according to the particular application in which the studs are being used. The will make this safety factor determination

3 Shear values are based on Tensile Strength of the stud.

Stored Arc Welding Studs – Tensile/Yield Strengths Mild Steel – 61,000 psi Ultimate, 50,000 psi Yield Stainless Steel – 75,000psi Minimum Ultimate, 30,000 psi Minimum Yield Aluminum – 21,000 psi Ultimate, 20,000 psi Yield Thread Diameter

6-32 UNC 8-32 UNC 10-24 UNC 10-32 UNF 1/4-20 UNC 1/4-28 UNF

Ultimate Tensile Load (lbs)

Yield Load (lbs)

Mild Steel

Stainless Steel

Aluminum

Mild Steel

Stainless Steel

Aluminum

458 705 870 1,005 1,585 1,810

687 1,057 1,305 1,507 2,377 2,715

192 296 365 422 666 760

321 493 609 704 1,110 1,267

275 423 522 603 951 1,086

183 282 348 402 634 724

General Information for Stud Welding Studs Stud Dimensions The length dimension, L, shown throughout the specification sheets is the overall, stud length before weld. The after weld in-place length will be shorter, depending on the size of the stud, the welding process, and weld settings. Approximate length reductions are shown in the table below. Stud Diameter

Weld Process

Length Reduction

10 (0.134”) and 12 gauge (0.105”) TPC pins

Stored Arc

--

6-32 through 1/4-20, ATC, ATS, ATA, and FTC studs

Stored Arc

1/32”

10 gauge (0.134”) P2P pins

Electric Arc

3/32”

3/16” through 1/2" diameter studs

Electric Arc

1/8”

5/8” through 7/8” diameter studs

Electric Arc

3/16”

1” diameter or larger studs

Electric Arc

1/4"

1/4" and 1/2" H4L Weld Through Metal Deck

Electric Arc

3/16 – 1/4”

5/8” H4L Weld Through Metal Deck

Electric Arc

5/16” – 3/8”

3/4" S3L Weld Through Metal Deck

Electric Arc

3/8” – 7/16”

M6 and 6mm diameter studs

Electric Arc

2mm

M8, 8mm, M10, 10mm, and M12 diameter studs

Electric Arc

3mm

12mm, M16, and 16mm diameter studs

Electric Arc

4mm

M20, 19mm, and 20mm diameter studs

Electric Arc

5mm

M24, 22mm, and 24mm diameter studs

Electric Arc

6mm

The stud length reduction is also often known as “burn-off.” The stud end configuration (chamfer, concentricity, and manufacturer’s identification) of studs and pins will be selected at our option, depending on production requirements.

Threads The standard external threads on studs are UNC-2A, and internal threads are UNC-2B, prior to plating. Other threads are available upon request. Standard maximum thread length is 3”. Whenever possible, threads are cold-rolled. The surface quality and strength of rolled threads is greatly improved compared to cut threads. The surface finish on rolled threads is less subject to wear and offers more corrosion resistance than cut threads.

Flux Flux quality and quantity is an essential factor for obtaining consistent weld quality. All standard stud weld Nelson studs 5/16” diameter and greater have a solid flux load. Rectangular studs up to 1/8” x 5/8”are not fluxed.

Plating Plating is useful to increase a stud’s corrosion resistance wear. Unless otherwise specified at the time of order, all Nelson studs will be supplied unplated. Upon request, the following types of surface protection are available: Zinc Plating – ASTM B-633 Zinc Dichromating – ASTM B633 Fe/Zn 8

Copper Plating Nickel Plating

Zinc plating will adversely affect the weld quality. For this reason, the weld ends of stud weld studs are not plated.

Annealing Nelson studs can be annealed to a maximum of 75 Rockwell B hardness (HRB) for low carbon steel and 85 HRB for stainless steel. An extra charge is applicable for annealing and will be quoted if specified at the time of order.

Ferrules For weld integrity, certain stud types must be welded using a ceramic ferrule. Appropriate ceramic ferrules are included in the stud purchase price. Ferrules will be shipped with studs, when required. Ferrules for welding special applications should be specified when orders for studs are placed.

Accessories Accessories depend on the stud type, diameter, length and the ferrule being used, along with any specific fixturing or job conditions or restrictions. For accessory information, please refer to the stud, ferrule, and accessory specifications.

General Information for Stud Welding Studs Weld Flash When a stud is end-welded, weld metal forms around its base. The weld flash dimension is controlled by the design of the ferrule used. The diameter of the weld metal is generally larger than the diameter of the stud. Consideration is required in the design of mating parts that involve weld flash. Refer to the appropriate stud specification sheets for recommended weld flash clearance hole diameters.

Ordering Each stud ordered from Nelson Stud Welding should be listed separately along with the appropriate ferrule. The stud style should be specified as well as the length, diameter, material, quantity, and any other information according to the stud specification sheet. Your Nelson representative will be happy to advise you on the accessories required for welding the stud ordered, and is also available to aid in determining the proper stud for your application requirements.

Weight Charts for Shipping Approximate Weight of Threaded Studs per 1000 (length before welding is used to determine weight) Weights are in pounds. To convert to kilograms, multiply values below by 0.4536 Stud Length

Diameter 1/4

5/16

3/8

7/16

1/2

5/8

3/4

7/8

3/4

8.3

12.8

18.8

25.5

34.5

--

--

--

1

11.0

17.0

25.0

34.0

46.0

70.0

--

--

1-1/4

13.8

21.3

31.3

42.5

57.5

87.5

133.8

--

1-1/2

16.5

25.5

37.5

51.0

69.0

105.0

160.5

243.8

1-3/4

19.3

29.8

43.8

59.5

80.5

122.5

187.3

284.4

2

22.0

34.0

50.0

68.0

92.0

140.0

214.0

325.0

2-1/4

24.8

38.3

56.3

76.5

103.5

157.5

240.8

365.6

2-1/2

27.5

42.5

62.5

85.0

115.0

175.0

267.5

406.3

2-3/4

30.3

46.8

68.8

93.5

126.5

192.5

294.3

446.9

3

33.0

51.0

75.0

102.0

138.0

210.0

312.0

487.5

3-1/4

35.8

55.3

81.3

110.5

149.5

227.5

347.8

528.1

3-1/2

38.5

59.5

87.5

119.0

161.0

245.0

374.5

568.8

3-3/4

41.3

63.8

93.8

127.5

172.5

262.0

401.3

609.4

4

44.0

68.0

100.0

136.0

184.0

280.0

428.0

650.0

4-1/4

46.8

72.3

106.3

144.5

195.5

297.5

454.8

690.6

4-1/2

49.5

76.5

112.5

153.0

207.0

315.0

481.5

731.3

4-3/4

52.3

80.8

118.8

161.5

218.5

332.5

508.3

771.9

5

55.0

85.0

125.0

170.0

230.0

350.0

535.0

812.0

Each Additional Inch

11.0

17.0

25.0

34.0

46.0

70.0

107.0

162.5

Add for Collar Studs

5.8

7.2

9.0

12.8

13.0

--

--

--

Ferrule

2.0

2.5

3.0

3.5

4.0

5.0

10.0

12.0

General Information for Stud Welding Studs Approximate Weight of Unthreaded Studs per 1000 (length before welding is used to determine weight) Weights are in pounds. To convert to kilograms, multiply values below by 0.4536 Diameter

Length

3/16

1/4

5/16

3/8

7/16

1/2

5/8

3/4

7/8

3/4

6.0

10.5

16.4

23.5

31.9

41.7

--

--

--

1

8.0

14.0

21.8

31.3

42.5

55.6

86.6

--

--

1-1/4

10.0

17.5

27.3

39.1

53.1

69.5

108.3

156.0

--

1-1/2

12.0

21.0

32.7

47.0

63.8

83.4

129.9

187.2

255.0

1-3/4

14.0

24.5

38.2

54.8

74.4

97.3

151.6

218.4

297.5

2

16.0

28.0

43.6

62.6

85.0

111.2

173.2

249.6

340.0

2-1/4

18.0

31.5

49.1

70.4

95.6

125.1

194.9

280.8

382.5

2-1/2

20.0

35.0

54.5

78.3

106.3

139.0

216.5

312.0

425.0

2-3/4

22.0

38.5

60.0

86.1

116.9

152.9

238.2

343.2

467.5

3

24.0

42.0

65.4

93.9

127.5

166.8

259.8

374.4

510.0

3-1/4

26.0

45.5

70.9

101.7

138.1

180.7

281.5

405.6

552.5

3-1/2

28.0

49.0

76.3

117.4

148.8

194.6

303.1

436.8

595.0

3-3/4

30.0

52.5

81.8

125.2

159.4

208.5

324.8

468.0

637.5

4

32.0

56.0

87.2

125.2

170.0

222.4

346.4

499.2

680.0

4-1/4

34.0

59.5

92.7

133.0

180.6

236.3

368.1

530.4

722.5

4-1/2

36.0

63.0

98.1

140.9

191.3

250.2

389.7

561.6

765.0

4-3/4

38.0

66.5

103.6

148.7

210.9

264.1

411.4

592.8

807.5

5

40.0

70.0

109.0

156.5

212.5

278.0

433.0

624.0

850.0

Each Additional Inch

8.0

14.0

21.8

31.3

42.5

55.6

86.6

124.8

170.0

Ferrule

3.0

3.5

4.0

5.0

6.0

7.5

9.0

27.0

37.0

Approximate Weight of Shear Connectors (length before welding is used to determine weight) Weights are in pounds. To convert to kilograms, multiply values below by 0.4536 S3L Shear Connector Description

Small Shear Cartons Weight Per Box, w/o Box

Quantity Per Box

Quantity Per Pallet

Weight Per 1000 Pieces

Net Weight of Pallet

3/4 x 3-3/16

60.9

130

3,510

468

1,643

3/4 x 3-3/8

58.9

120

3,240

488

1,589

3/4 x 3-7/8

60.2

110

2,970

548

1,625

3/4 x 4-3/16

55.5

95

2,565

585

1,499

3/4 x 4-7/8

54.3

80

2,160

678

1,466

3/4 x 5-3/16

56.6

80

2,160

708

1,529

3/4 x 5-3/8

56.3

75

2,025

750

1,519

3/4 x 5-7/8

56.6

70

1,890

794

1,529

3/4 x 6-3/16

49.8

60

1,620

825

1,345

3/4 x 7-3/16

51.9

55

1,485

946

1,403

3/4 x 8-3/16

42.9

40

1,080

1067

1,158

7/8 x 3-11/16

61.3

85

2,295

726

1,656

7/8 x 4-3/16

60.0

75

2,025

811

1,642

7/8 x 5-3/16

58.2

60

1,620

980

1,584

7/8 x 6-3/16

56.6

50

1,350

1153

1,528

7/8 x 7-3/16

52.0

40

1,080

1320

1,426

7/8 x 8-3/16

49.9

35

945

1473

1,391

General Information for Stud Welding Studs Approximate Weight of Headed Anchors (length before welding is used to determine weight) Weights are in pounds. To convert to kilograms, multiply values below by 0.4536 Small Shear Cartons H4L Headed Anchor Weight Per Quantity Per Quantity Per Weight Per 1000 Description Box, w/o Box Box Pallet Pieces

Net Weight of Pallet

1/4 x 2-11/16

44.0

1000

27,000

44

1/4 x 4-1/8

36.0

550

14,850

65

965

3/8 x 4-1/8

58.0

375

10,125

155

1,569

3/8 x 6-1/8

2937

140

3,780

212

802

1/2 x 2-1/8

67.0

400

10,800

170

1,836

1/2 x 3-1/8

60.0

275

7,425

226

1,678

1/2 x 4-1/8

50.0

180

4,860

282

1,370

1/2 x 5-5/16

41.0

120

3,240

341

1,107

1/2 x 6-1/8

40.1

105

2,835

393

1,114

1/2 x 8-1/8

33.0

65

1,755

504

885

5/8 x 2-11/16

61.0

195

5,265

315

1,658

5/8 x 4-3/16

55.0

125

3,375

450

1,518

5/8 x 6-9/16

45.0

70

1,890

652

1,232

5/8 x 8-3/16

40.0

50

1,350

79.

1,070

Above weights do not include weight of box. Empty shear carton: 1.00 lb. each Shear cartons: 27 per pallet

1,188

Pallet size: 36” x 36” Approximate volume of pallet: 18 cu. ft. (0.51 cu. meter)

Note: All dimensions have been calculated at the mean dimensions of the tolerance allowance, and will vary if the product is at a minimum or maximum of tolerance.

Insulation Fasteners - Quantity Per Carton Insulation Pin Type

Quantity Per Carton

Insulation Pin Type

Quantity Per Carton

10 ga. P2P less than 2-1/2” long

5,000

10 ga. and 12 ga. TPC less than 2-1/2” long

5,000

10 ga. P2P 3” long

4,000

10 ga. and 12 ga. TPC 2-1/2” through 6” long

2,500

10 ga. P2P 3-1/2” through 6” long

2,000 1” x 1-1/4” Rectangular Speed Clip

5,000

12 ga. CHP with 1-3/16” dia. head, all lengths

1,000

1-1/2” Square Speed Clip

3,000

10 ga. CHP with 1-1/2” dia. head, all lengths

1,000

1-1/2” Round Speed Clip

5,000

10 ga. CHP with 1-1/2” dia. head, 2” through 3” long

500

2-1/2” Square Speed Clip

1,000

2” Round Speed Clip

1,000

Deliveries Delivery on stock items will be made within three (3) days following the date of order receipt. Non-stock items or special items, which require manufacture, will be acknowledged in writing with a delivery promise.

Extra Charges Stock items are not subject to additional charges. With approval from Nelson, a non-stock item may be given production priority if required before the acknowledged delivery date. Should such a service be required and approved, the customer will be charged an extra “break-in” fee. A non-stock or special stud that requires manufacturing may be subject to a set-up charge for setting dies onto the machines and changing production processes. Packing other than standard and export packaging is subject to extra charge. Quotation will be made on request.

For stud diameters, lengths, and materials other than shown, consult your Nelson Sales Representative. Nelson Stud Welding, Inc. reserves the right to alter technical specifications at any time. Consult your Nelson sales engineer for additional engineering information.

NELSON STUD WELDING SPECIFICATION: CKA Aluminum Collar Studs

CKA

Nelson CKA aluminum collar studs are available in thread sizes of 1/4-20 through 1/2-13. They are used for attaching parts to aluminum structures. They are welded using ceramic ferrules in conjunction with argon as a shielding gas. The collar on CKL studs is useful in mounting applications where a standoff is needed. The shielding gas is introduced to the weld area through a gas foot assembly, #751020000, which is used for all diameters of CKA studs. Gas hose #515001001 and gas regulator #514001001 are needed to deliver and control the gas flow from a pressurized cylinder.

An aluminum Tranquil-Arc® plunge dampener kit is also needed as an accessory on the gun to control the rate of the stud’s return in to the molten weld metal at the end of the weld cycle. Studs are available in before weld lengths greater than the specified minimum length to a maximum of 4-1/8”. For similar function studs, please refer to Nelson HBA Threaded Full Base studs and TBA Internally Threaded studs. When ordering, specify Type, Base Diameter, Base Length, Thread Size, Extension Length, Material, Quantity, and Part Number Example: CKA 0.330 x 1.125, 3/8-16 x 3/4"; Aluminum; 10,000 pieces; #101015642 Thread Size

Stud Diameter D

C

Minimum Stud Length L

Maximum B

G

H

Burn Off

Flash Clearance

Required Standard Accessories Ferrule Chuck

1/4-20

1/4

0.215

1.250

0.406

1.250

0.093

0.125

0.469

100101047

5/16-18

5/16

0.275

1.250

0.468

1.250

0.093

0.156

0.531

100101048

500001007 500001009

3/8-16

3/8

0.330

1.250

0.603

1.250

0.093

0.187

0.656

100101049

500001011

7/16-14

7/16

0.387

1.250

0.656

1.250

0.093

0.218

0.750

100101050

500001012

1/2-13

1/2

0.448

1.250

0.750

1.250

0.093

0.250

0.843

100101051

500001014

MATERIALS: CKA Studs are available in 5356-H32 Aluminum. For specific grade information and physical and chemical properties, as well as information on heat treating, please see General Material Specifications. THREADS: Standard external threads are UNC-2A.

Visit our website www.NelsonStudWelding.com for a list of our standard stock products. Nelson Stud Welding, Inc. 7900 West Ridge Road Elyria, Ohio 44035

PH 1-800-NEL-WELD 1-800-635-9353

E-mail: [email protected]

1/04

HBA

NELSON STUD WELDING SPECIFICATION: HBA Full Base Threaded Aluminum Studs Nelson HBA threaded aluminum studs are available in thread sizes of #10-24 through 1/2-13. They are used for attaching parts to aluminum structures. They are welded using ceramic ferrules in conjunction with argon as a shielding gas. The full nominal weld base for the HBL studs gives greater weld reliability and strength than could be achieved using a pitch diameter weld base. The shielding gas is introduced to the weld area through a gas foot assembly, #751020000, which is used for all diameters of HBA studs. Gas hose #515001001 and gas regulator #514001001 are needed to deliver and control the gas flow from a pressurized cylinder.

An aluminum Tranquil-Arc plunge dampener kit is also needed as an accessory on the gun to control the rate of the stud’s return in to the molten weld metal at the end of the weld cycle. For similar function, please refer to Nelson NBA Unthreaded Aluminum studs and TBA Internally Threaded Aluminum studs. When ordering, specify Type, Diameter, Before Weld Length, Material, Quantity, and Part Number Example: HBA 3/8-16 x 2-1/2”; Aluminum; 10,000 pieces; #101044056 Thread Size

Stud Diameter D

Minimum Unthreaded A

Minimum Stud Length L

E

F

#10-24

3/16

.312

.812

0.330

1/4-20

1/4

.312

.937

5/16-18

5/16

.343

.937

Weld Flash Size

Required Standard Accessories Ferrule Chuck

Burn Off

Flash Clearance

0.093 0.093

0.390

100101046

500001005

0.406

0.125 0.125

0.469

100101047

500001007

0.468

0.156

0.093

0.531

100101048

500001009

0.093

500001011

3/8-16

3/8

.390

.937

0.603

0.187

0.656

100101049

7/16-14

7/16

.468

.937

0.656

0.218

0.093

0.750

100101050

500001012

1/2-13

1/2

.515

.937

0.750

0.250

0.125

0.843

100101051

500001014

MATERIALS: HBA Studs are only available in 5356 Aluminum. For specific grade information and physical and chemical properties, conforming standards, and information on heat treating, please see General Material Specifications. THREADS: Standard external threads are UNC-2A. The standard maximum length of threads on all HBA aluminum studs is 1-1/4”.

Visit our website www.NelsonStudWelding.com for a list of our standard stock products. Nelson Stud Welding, Inc. 7900 West Ridge Road Elyria, Ohio 44035

PH 1-800-NEL-WELD 1-800-635-9353

E-mail: [email protected]

2/09

NELSON STUD WELDING SPECIFICATION: N3A Aluminum Navy Type Annular Pin

N3A

N3A Navy pins are welded for the attachment of insulation. The insulation is impaled over the welded studs and retained with caps that are driven onto the studs, and lock onto the annular rings. The 5/16” diameter welded end on Nelson N3A pins permits welding without the use of inert gas shielding, which is normally required when welding aluminum studs. The flat top caps for use with N3A studs are usually supplied in aluminum. They can also be supplied in plated mild steel or stainless steel, per the N3P Annular Ring stud. The standard N3A cap is shown below and is supplied in aluminum. For similar function studs, see Nelson N3P Annular Ring Navy Pin, P2P Double Pointed Insulation Pins, TPC Single Pointed Insulation Pins, and CHP Cupped Headed Insulation Pins. When ordering, specify Type, Description, Material, Quantity, and Part Number Example: N3A 3/16 x 1”; Mild Steel; 10,000 pieces; #101074014 Stud Description

Minimum Length L

D

A

B

C

Ferrule

Chuck

Grip

Foot

3/16 x L

1.000

0.178

0.250

0.176

0.312

100101007

500001005

501001006

502001137

Required Standard Accessories

MATERIALS: Studs are available in Aluminum. For specific grade information and physical and chemical properties, and conforming standards, please see General Material Specifications.

Recommended Accessories: SPECIFICATION: Cap for N3A and N3P Pins Caps are used in conjunction with Nelson N3A and N3P pins to secure many types of insulation to steel plate. When ordering, specify Type, Description, Material, and Quantity Example: N3A Insulation Cap Aluminum 10,000 pieces Description Part Number Insulation Cap

101304002

Materials: The Navy pin cap is supplied in Aluminum. For specific grade information and physical and chemical properties, and conforming standards, please see General Material Specifications.

Visit our website www.NelsonStudWelding.com for a list of our standard stock products. Nelson Stud Welding, Inc. 7900 West Ridge Road Elyria, Ohio 44035

PH 1-800-NEL-WELD 1-800-635-9353

E-mail: [email protected]

1/04

NELSON STUD WELDING SPECIFICATION: NBA Unthreaded Aluminum Studs

NBA

Nelson NBA unthreaded aluminum studs are available in diameters of 3/16” through 1/2". They are used as mounting, pivot, and stop pins on aluminum structures. They are welded using ceramic ferrules in conjunction with argon as a shielding gas. The shielding gas is introduced to the weld area through a gas foot assembly, #751020000, which is used for all diameters of NBA studs. Gas hose #515001001 and gas regulator #514001001 are needed to deliver and control the gas flow from a pressurized cylinder.

An aluminum Tranquil-Arc® plunge dampener kit is also needed as an accessory on the gun to control the rate of the stud’s return in to the molten weld metal at the end of the weld cycle. For similar function, please refer to Nelson HBA Threaded Aluminum studs and TBA Internally Threaded studs. When ordering, specify Type, Diameter, Before Weld Length, Material, Quantity, and Part Number Example: NBA 1/2 x 3”; Mild Steel; 10,000 pieces; #101074014 Stud Diameter D

Minimum Stud Length L

Burn Off

Weld Flash Size E

F

Flash Clearance

Required Standard Accessories Ferrule

Chuck

3/16

0.812

0.093

0.330

0.125

0.390

100101046

500001005

1/4

0.937

0.093

0.406

0.125

0.469

100101047

500001007

5/16

0.937

0.093

0.468

0.156

0.531

100101048

500001009 500001011

3/8

0.937

0.093

0.603

0.187

0.656

100101049

7/16

0.937

0.093

0.656

0.218

0.750

100101050

500001012

1/2

0.937

0.125

0.750

0.250

0.843

100101051

500001014

MATERIALS: NBA Studs are only available in Aluminum. For specific grade information and physical and chemical properties, as well as information on heat treating, please see General Material Specifications.

Visit our website www.NelsonStudWelding.com for a list of our standard stock products. Nelson Stud Welding, Inc. 7900 West Ridge Road Elyria, Ohio 44035

PH 1-800-NEL-WELD 1-800-635-9353

E-mail: [email protected]

1/04

NELSON STUD WELDING SPECIFICATION: SBA Threaded Aluminum Shoulder Stud

SBA

Nelson SBA shoulder studs have a weld base diameter larger than the threaded extension diameter. They are available in weld base diameters 1/4” through 1/2”, with threaded extension sizes up to 7/16-14. The Nelson SBL studs are used as mountings for s and hardware where a standoff shoulder is needed. SBA studs are similar to CKA aluminum collar studs, but the larger weld base provides improved bend resistance. Both chuck size and part number are determined by the thread size, C. Please refer to the Nelson HBA stud specification sheet to find the appropriate chuck size and number. Nelson SBA studs are welded using ceramic ferrules in conjunction with argon as a shielding gas. The shielding gas is introduced through a gas foot assembly, #751020000, which is used for all diameters of SBA studs. Gas hose #515001001 and a gas regulator #514001001 are needed to deliver and control the gas flow from a pressurized cylinder. An aluminum Tranquil-Arc® plunge dampener kit is also needed as an accessory on the gun to control the rate of the stud’s return to the molten weld metal at the end of the weld cycle. For similar function aluminum studs, please refer to Nelson CKA Threaded Aluminum Collar studs, HBA Threaded Full Base studs, and TBL Internally Threaded studs. When ordering, specify Type, Base Diameter, Base Length, Extension Thread Size, Extension Length, Material, Quantity, and Part Number Example: SBA 1/2 x 1; 3/8-16 x 3/4”; Aluminum; 10,000 pieces; #101093660 Maximum Standard Major Thread Maximum Diameter Diameter Length D C A

Minimum Length L

#10-24

0.312

1/4

0.468

Weld Fillet Dimensions E

F

0.406

0.125

Required Standard Accessories Ferrule

Grip

Foot

100101047

501001007

500001007

5/16

1/4-20

0.635

0.343

0.468

0.156

100101048

501001006

500001009

3/8

5/16-18

0.781

0.390

0.603

0.187

100101049

501001009

500001011

7/16

3/8-16

0.937

0.468

0.656

0.218

100101050

501001008

500001012

1/2

7/16-14

0.937

0.500

0.750

0.250

100101151

501001011

500001014

MATERIALS: Studs are available in 5356 Aluminum. Material selection is dependent on anticipated service temperature range. For specific grade information and physical and chemical properties, conforming standards, and information on heat treating, please see General Material Specifications. THREADS: Standard external threads are UNC-2A.

Visit our website www.NelsonStudWelding.com for a list of our standard stock products. Nelson Stud Welding, Inc. 7900 West Ridge Road Elyria, Ohio 44035

PH 1-800-NEL-WELD 1-800-635-9353

E-mail: [email protected]

1/04

NELSON STUD WELDING SPECIFICATION: TBA Internally Threaded Aluminum Studs

TBA

Nelson TBA internally threaded aluminum studs are available with weld base diameters of 1/4” through 1/2", with thread sizes of #10-24 through 1/2-13. They are used as mounting points on aluminum structures. They are welded using ceramic ferrules in conjunction with argon as a shielding gas. The shielding gas is introduced to the weld area through a gas foot assembly, #751020000, which is used for all diameters of TBA studs. Gas hose #515001001 and gas regulator #514001001 are needed to deliver and control the gas flow from a pressurized cylinder. An aluminum Tranquil-Arc® plunge dampener kit is also needed as an accessory on the gun to control the rate of the stud’s return in to the molten weld metal at the end of the weld cycle. The minimum length of Nelson TBA studs, shown below, is the before weld length of the stud, and is dependent on the thread depth. For similar function aluminum studs, please refer to Nelson HBA Externally Threaded Aluminum studs, SBA Aluminum Shoulder studs, and CKA Aluminum Collar studs. When ordering, specify Type, Diameter, Before Weld Length, Tap Size, Tap Depth, Material, Quantity, and Part Number Example: TBA 1/2 x 1”; tap 3/8-16 x 9/16”; 5356 Aluminum; 10,000 pieces; #10108478 Stud Diameter D

Minimum Stud Length, L

Maximum Tap Diameter C

D = 1/2 max

D = 5/8 &3/4

Weld Base Diameter

Burn Off

Weld Flash Size E

F

Flash Clearance

Required Standard Accessories Ferrule

Chuck

1/4

10-24

0.937

N/A

1/4

0.093

0.406

0.125

0.469

100101047

500001007

5/16

1/4-20

1.062

1.500

5/16

0.093

0.468

0.156

0.531

100101048

500001009

3/8