Unimec Screw Jack 6ol23

This document was ed by and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this report form. Report 445h4w

Overview 1s532p

& View Unimec Screw Jack as PDF for free.

More details 6h715l

- Words: 22,198

- Pages: 74

Ease of use and high reliability make UNIMEC trapezoidal screw jacks suitable for a wide variety of uses. They can be employed to lift, pull, move, or align any kind of loads, with a perfect synchronism which can hardly be obtained with other handling methods. UNIMEC trapezoidal screw jacks are absolutely irreversible, that is, they can their applied loads without needing any brakes or other locking systems. The screw jacks can be employed singularly or in groups properly connected with shafts, ts, and/or bevel gearboxes. They can be driven by different motors: electrical, with either alternating or direct current, as well as hydraulic or pneumatic motors. Also they can be driven manually or with any other type of transmission. In addition to the models shown on the following pages, UNIMEC can produce custom designed screw jacks to meet all the requirements. UNIMEC trapezoidal screw jacks are designed and manufactured using innovative technology so to supply a product which identifies itself with the state of the art in the transmission devices.

trapezoidal screw jacks The highest quality and a 28 years long experience are able to meet the most demanding and sophisticated requirements. The outer surfaces are completely machine finished and the parts are assembled with special care, in order to allow the application of s, flanges, pins, or any other components a project may require.The application of double guides throughout the product line provides a very good running efficiency even under the most strenuous operating conditions. Special sealing systems enable the inner gears to operate in a bath of lubricant, which guarantees them a long lasting life.

18

19

60 TP Threaded spindle model with translating threaded spindle. The rotation of the worm screw is transformed in the axial movement of the threaded spindle by means of the worm wheel. The threaded spindle must have a rotational constraint.

62 TPR Threaded spindle model with rotating threaded spindle. The rotation of the worm screw actuates the movement of the worm wheel which causes the threaded spindle to move, being fixedly connected to it. The external nut (lead nut), transforms the rotational movement of the threaded spindle into a linear movement. The nut must have a rotational constraint.

67 MTP TP model screw jacks arranged for direct coupling to single phase, three-phase, selfbraking, direct current, hydraulic, pneumatic motors etc.

67 MTPR TPR model screw jacks arranged for direct coupling to single phase, three-phase, selfbraking, direct current, hydraulic, pneumatic motors etc.

20

Application samples are online at www.unimec.eu - section Applications

CTP TP model screw jacks arranged for direct coupling to single phase, three-phase, selfbraking, direct current, hydraulic, pneumatic motors, etc. by means of a bell house and a t.

CTPR TPR model screw jacks arranged for direct coupling to single phase, three-phase, selfbraking, direct current, hydraulic, pneumatic motors, etc. by means of a bell house and a t.

RTP TP model screw jacks arranged for direct coupling to reducers or worm screw or coaxial motor reducers, etc.

RTPR TPR model screw jacks arranged for direct coupling to reducers or worm screw or coaxial motor reducers, etc.

VARIOUS END FITTINGS 64

BU 70 TP model screw jack with anti-withdrawing bush

PRO 68 TP model screw jacks with oil bath rigid protection.

CU 69 TP model screw jack oil proof assembled

PRF 71 TP model screw jacks with rigid protection and stroke control.

PE 72 TP model screw jacks with elastic protection.

PE 72 TPR model screw jacks with elastic protection.

Application samples are online at www.unimec.eu - section Applications

21

production line

PR 67 TP model screw jacks with rigid protection.

74 PRA TP model screw jacks with rigid protection and dual-guide anti-rotation.

75 AR TP model screw jacks with grooved anti-rotation spindle.

76 CS TP model screw jacks with safety lead nut for monitored wear control.

76 CS TPR model screw jacks with safety lead nut for monitored wear control.

22

Application samples are online at www.unimec.eu - section Applications

77 CSU TP model screw jacks with safety lead nut for automatic wear control.

77 CSU TPR model screw jacks with safety lead nut for automatic wear control.

78 SU TP model screw jacks with lead nut for monitored wear control.

78 SU TPR model screw jacks with lead nut for monitored wear control.

SUA 79

SUA TPR model screw jacks with lead nut for automatic wear control.

79

RG 80 TP model screw jacks with anti axial backlash lead nut.

RG 80 TPR model screw jacks with anti axial backlash lead nut.

CR 81 TP model screw jacks with worm wheel rotation control.

CR 81 TPR model screw jacks with worm wheel rotation control.

CT 81 TP-TPR model screw jacks with casing temperature control.

CTC 81 TPR model screw jack with lead nut temperature control.

Application samples are online at www.unimec.eu - section Applications

23

production line

TP model screw jacks with lead nut for automatic wear control.

82 SP TP model screw jacks with additional mounting plates.

82 SP TPR model screw jacks with additional mounting plates.

83 FP TP model screw jacks with -through holes for bolts.

83 FP TPR model screw jacks with -through holes for bolts.

24

Application samples are online at www.unimec.eu - section Applications

84 PO TP model screw jacks with rigid rocking protection.

85 P TP model screw jacks with lateral pins.

85 P TPR model screw jacks with lateral pins.

86 DA Double action TPR model screw jacks.

FD 87 TPR model screw jacks for fast disassembling of the trapezoidal spindle.

AM 88 TP model screw jacks with over-size spindle.

TP model screw jacks with special end fittings.

TP model screw jacks with telescopic spindle.

AM 88 TPR model screw jacks with over-size spindle.

METAL PROTECTION

Application samples are online at www.unimec.eu - section Applications

25

production line

TP model screw jacks with metal protection.

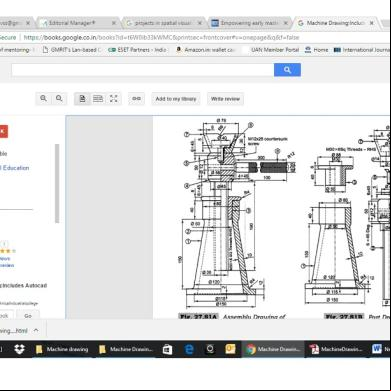

Models TP model: threaded spindle with axial translation. The input rotation of the worm screw is transformed in the axial translation of the threaded spindle by means of the worm wheel. The load is applied on the threaded spindle which must have a rotational constraint.

Tr a p e z o i d a l s c r e w j a c k s TPR model: with rotational threaded spindle and external nut (lead nut). The input rotation of the worm screw causes the rotation of the threaded spindle which is attached to the worm wheel. The load is applied to an external nut (lead nut) which must have a rotational constraint.

End fittings To meet the widest possible range of needs, various types of end fittings are available, which can be custom made upon request.

Casings Casings are made of various materials depending on the size of screw jacks. For screw jacks of the 183 series, casings are made of cast aluminium AlSi12 (according to the UNI EN 1706:1999 requirements), for the series between the sizes 204 and 9010, casings are made of grey cast iron EN-GJL-250 (according to the UNI EN 1561:1998 requirements); and for the extra heavy series, from size 10012, the casing is made of electro-welded carbon steel S235J0 (according to the UNI EN 10025-2:2005 requirements).

Worm screws For the entire screw jacks line, worm screws are made of a special steel 16NiCr4 (according to the UNI EN 10084:2000).They undergo thermal treatments like case-hardening and carburizing before being thoroughly ground both on the threads and on the tangs.

Worm wheel and nut The worm wheels and nuts (lead nuts) are made of a special high-resistance aluminium bronze CuAI10Fe2-C (according to the UNI EN 1982:2000 requirements). The trapezoidal geometry of the threading meets the requirements of the ISO 2901:1993 norm. The worm wheels toothing profile has been designed especially for our screw jacks and can easily a heavy-duty use.

Threaded spindles The threaded spindles are mainly manufactured by rolling carbon steel C 45 grounded bars (according to the UNI EN 10083-2:1998 requirements). Said process, which is temperature controlled, allows to include in our standard production 6 meter long bars. The trapezoidal geometry of the threading meets the requirements of the ISO 2901:1993 norm. Threaded spindles made of stainless steel AISI 316 or other materials can be manufactured upon request for length up to 12 meters.

Protections Protections can also be applied in order to prevent dust and foreign matters from coming into with the coupling and causing damages to the threaded spindle and its nut. For TP models, a steel rigid tube can be provided on the back side, while the front side can be protected by polyester and PVC elastic bellows. In TPR models only elastic protections can be applied.

Bearings and market materials Top-quality bearings and market materials are used for the whole line.

26

C Ce Ct DX Frv fa fs ft Mtm Mtv N n P Pi Pe Pu rpm SX v ηm ηc ηs ωm ωv

= = = = = = = = = = = = = = = = = = = = = = = =

unit load to be handled [daN] equivalent unit load [daN] total load to be handled [daN] left hand spiral threading radial forces on the worm screw [daN] ambient factor service factor temperature factor torque on the drive shaft [daNm] torque on the worm screw [daNm] number of screw jacks and bevel gearboxes under a single handling number of screw jacks under a single handling mounting power requirement [kW] input power to the single screw jack [kW] equivalent power [kW] output power to the single screw jack [kW] rounds per minute left hand spiral threading axial translation speed of the load [mm/min] screw jack running efficiency configuration running efficiency structure running efficiency motor angular speed [rpm] worm screw angular speed [rpm]

Unless otherwise specified all dimensional tables show linear measurements expressed in [mm]. All the reduction ratios are expressed in the form of a fraction, unless otherwise specified.

27

components specifications and glossary

GLOSSARY

LOAD ANALYSIS AND COMPOSITION Choosing the right screw jack, and hence also its proper functioning, mostly depends on the identification of the real load acting on the screw jack. Loads can be divided in two main groups: static loads and dynamic loads; these groups are further made-up of: traction loads, compression loads, lateral loads, radial loads, eccentric loads, loads from shocks, loads from vibrations. STATIC LOADS A static load is the force that will be applied to the screw jack transmission devices while they are not in motion. DYNAMIC LOADS A dynamic load is the force that will be applied to the screw jack transmission devices while they are in motion. TRACTION LOADS A traction load is the force applied to the threaded spindle axis with an opposite direction to the casing.

COMPRESSION LOADS A compression load is a force applied to the threaded spindle axis with the same direction as the casing.

LATERAL LOADS A lateral load is a force applied perpendicular to the threaded spindle axis.

ECCENTRIC LOADS An eccentric load is a force whose centre of application does not belong to the threaded spindle axis, even having the same direction.

28

LOADS FROM SHOCKS A load from shocks is a load where the impulse forces generated by an impact are not quantifiable. LOADS FROM VIBRATIONS A load from vibrations is applied when a shock load increases the impulse frequency. Depending on the type of load some solution must be applied during the design phase: STATIC TRACTION LOAD The maximum applicable load for all models and sizes is shown in the specification tables. Shocks and/or lateral loads limit its applications. DYNAMIC TRACTION LOAD The maximum dynamic traction load which can be applied to a screw jack does not only depend on its size: it could be limited by the ambient temperature, service factors and possible lateral loads and/or shocks. It is thus necessary to check all those parameters. STATIC COMPRESSION LOAD The maximum load which can be applied is determined by the length of the threaded spindle as well as by the constraints it undergoes.The limit applicable load can be obtained on the basis of the Euler diagrams. Its application could be limited by possible shocks and/or lateral loads. DYNAMIC COMPRESSION LOAD The maximum compression load which can be applied is determined by many factors: the length of the threaded spindle, the ambient temperature, service factors and possible lateral loads and/or shocks. In addition to all the verifications already foreseen in the case of a traction load, further verifications are necessary relative to the Euler diagrams. STATIC LATERAL LOAD This kind of load induces a lateral shifting of the threaded spindle causing a damaging bending which limits the ability of the screw jack. Suitable graphs show the maximum lateral load values according to the length and size of the threaded spindle. For any further and more detailed verifications our technical office is at your disposal. DYNAMIC LATERAL LOAD A lateral load in dynamic applications is not allowed. In case of essential use of screw jacks with lateral load is for machine requirements, it will be necessary to our technical office. ECCENTRIC STATIC LOAD An eccentric load in static applications induces the same problems as the lateral loads. For this reason the above considerations are also applicable to this kind of load. DYNAMIC ECCENTRIC LOAD In case of handling an eccentric load, in order to avoid problems due to lateral load, it is necessary to create a suitably guided and sized mechanical structure, in order to absorb all the lateral components of the load. The guide must be realized very carefully: too narrow backlashes could cause seizure and stick-slips, while too rough backlashes would make useless the construction of the guide itself.

DYNAMIC LOAD FROM VIBRATIONS OR SHOCKS A dynamic load from vibrations or from shock can be damaging for the screw jack: stick-slip phenomena and consequent local overloads can enormously increase the wear conditions. It is necessary to minimize the shocks entity and the vibrations width

29

loads

STATIC LOAD FROM VIBRATIONS OR SHOCKS A load from vibrations or from shock, if not very heavy, could be the only reasons for the reversibility of the transmission moved by the screw jack. In that case it is advisable to our technical office in order to the screw jack applicability.

BACKLASH Backlash on the worm screw The worm screw – worm wheel coupling has a small degree backlash. Due to the reduction ratio and the transformation from the rotation movement to the translation movement, this backlash becomes an error of less than 0,05 mm in the linear positioning of the threaded spindle.

Lateral backlash in TP models The thread spindle and worm wheel coupling presents a natural and necessary lateral backlash indicated by A in the drawing below.The use of a double serial guide allows to minimize the entity of said backlashes, while keeping the spindle and nut axes aligned. The angular backlash on the coupling is translated on the spindle end fitting into a linear measure whose value depends on the size of the screw jack and grows according to the length of the spindle itself. Traction loads tend to reduce this backlash, while compression loads induce the opposite effect.

Lateral backlash in TPR models In TPR models the spindle and the worm wheel are locked by means of a double pins. UNIMEC carries out this operation by means of a suitable machine which keeps the axes of the two components coincident during the two drillings and the consequent pins insertions. Hence, the threaded spindle rotates minimizing the oscillations due to concentricity errors. For a proper operation it is necessary for the to provide solutions able to keep the spindle and the lead nut aligned.The guides can be external or directly implicate the structure of the lead nut, as can be seen in the following drawings. Drawing A: the lead nut is connected to the load by means of particular screws which allow it to fit into the threaded spindle position. The guides must be realized externally. Drawing B: The lead nut, which has been properly milled, is connected to the load by means of brackets which ensure anti-rotation. The brackets must be realized externally. Drawing C:The lead nut, which has been properly milled, is connected to the load by means of brackets which ensure anti-rotation. The upper additional ring acts as a guide. Drawing D: The double ring guarantees a higher reliability with respect to the C system.

A

B

C

D

Axial backlash In B the axial backlash between the threaded spindle and its nut (either a worm wheel or a lead nut) is caused by the natural and necessary tolerance characterizing this kind of couplings. For construction purposes it is only important in the case where the load changes its direction of application. For applications where there can be reciprocating traction and compression loads, and therefore a need to compensate the axial backlash, it is possible to apply a backlash reduction system. The axial backlash reduction must not be forced in any case, in order to avoid that the screw and the nut get blocked.

30

HANDLINGS Manual operation All screw jacks in the series can be manually operated. The following table expresses in [daN] the maximum load that can be handled according to the reduction ratio of screw jacks, considering the application of a force of 5 daN on a handwheel having a radius of 250 mm. Obviously, greater loads can be manually handled by applying further reductions to the screw jack or by increasing the radius of the handwheel. Size fast ratio [daN] normal ratio [daN] slow ratio [daN]

183 500 500 -

204 1000 1000 1000

306 2000 2500 2500

407 1500 2900 5000

559 1000 2000 4300

7010 900 1600 3200

8010 860 1500 3200

Motorized operation Motors can be used for all jacks in the series. As a standard production, for the IEC unified motors, it is possible to connect them directly to screw jacks having a size between 204 and 8010. Special flanges can be made for hydraulic, pneumatic, brushless motors, as well as for direct current motors, permanent magnet motors, stepper motors and other special motors. In the case where it is not possible to motorize a screw jack directly, a connection by means of a bell house and a t can be foreseen. In special cases it is also possible to motorize size 183 and the s over 8010.The power tables determine, in case of unit service factors and for every single screw jack, the moving power and the input torque according to the size, the ratio, the dynamic load and the linear speed.

Rotation directions The rotation directions and the respective linear movements are showed in the drawings below. In standard conditions UNIMEC supplies screw jacks equipped with right handed worm screw, to which the movements illustrated in drawings 1 and 2 correspond. Upon request it is possible to have a left-handed worm screw, which the movements illustrated in drawings 3 and 4 correspond to. The combinations between threaded spindles and left-handed or right-handed worm screw, lead to the four combinations listed in the table below. We remind, that UNIMEC’s standard production does not include motorized left-handed worm screw.

1

DX DX Possible 1-2

2

DX SX Possible 3-4

3

SX DX Impossible 3-4

SX SX Impossible 1-2

4

Emergency operation In case of black-out, in order to be able to operate the single screw jacks or the complete structures by means of a crank, a free end on the screw jack worm screw or on the transmission is to be foreseen. In case of selfbraking motors or worm screw motor reducers, the brake must firstly be released and then it is necessary to disassemble those components from the transmission as the reducer could also be irreversible. It is advisable to equip the emergency operation mechanism with a safety device to cut the electric circuit.

31

backlashes and handling

Worm screw Threaded spindle Direct motorization on the worm screw Handling

LUBRICATION Inner lubrication The lubrication of the inner transmission devices to the casing is made, in the serial production, using a long lasting grease: TOTAL CERAN CA. It is an extreme pressure lubricant based on calcium sulfonate. For size 183, on the contrary, the TOTAL MULTIS MS 2 is used, which is a calcium-soap grease, suited for extreme pressures as well. In any case a plug is foreseen for all sizes (except for 183) in case of lubricant filling up. The technical specifications and the application field for the lubricant inside the casing are listed below. Lubricant

Application field

Operating temperature [°C]*

Technical specifications

standard

-15 : +130

standard (183)

-15 : +100

DIN 51502: OGPON -25 ISO 6743-9: L-XBDIB 0 DIN 51502: MPF2K -25 ISO 6743-9: L-XBCEB 2

Food industry

-10 : +150

Total Ceran CA Total Multis MS2 Total Nevastane HT/AW-1

NSF-USDA: H1

* for operating temperatures included between 80°C and 150°C Viton® seals should be used; for temperatures higher than 150°C, and lower than -20°C, it is advisable to our Technical office.

The quantity of lubricant contained in the screw jacks is listed in the following table. Size Inner lubricant quantity [kg]

183 0,06

204 0,1

306 0,3

407 0,6

559 1

7010 1,4

8010 1,4

9010 10012 12014 14014 16016 20018 25022 2,3 4 4 14 14 28 28

The threaded spindle The end is responsible for the lubrication of the threaded spindle which must be carried out using an adhesive lubricant, addicted for extreme pressures: Lubricant Rothen 2000/P Special

Application field

Operation temperature [°C]

Technical specifications

standard

0 : +200

Not foreseen

standard

0 : +150

AGMA 9005: D94 DIN 51517-3: CLP-US STEEL 224

Food industry

0 : +130

NSF-USDA: H1

(additive which can also be used pure)

Total Carter EP 2200 (not compatible with polyglicol oils)

Total Nevastane EP 1000

Lubricating the threaded spindle is an important and determining factor in the proper functioning of the screw jack. It must be carried out at regular intervals that can assure a constant coat of clean lubricant between the parts. Insufficient lubrication, the use of an oil without extreme pressure additives or an improper lubrication can lead to abnormal overheating and consequent wear phenomena, which naturally reduce the operating life of the screw jacks. In case the screw jacks are not visible or the threaded spindles are covered by protections, it is necessary to periodically the lubrication conditions. For heavier duties than those showed in the relative tables it is recommended to our Technical office.

32

Semi-automatic lubrication Many different systems of automatic lubrication are feasible, only the most common ones are listed as follows: 1 - For vertically mounted TP model screw jacks, it is possible to provide an oil bath rigid protection (with recirculation option) or, in case of high performances, a single chamber operation.This kind of lubrication will be described in details on page 68-69. 2 - Application of a additional ring on the cover in order to create a lubricant recovery tank. 3 - Use of a lubricant drop-applicator to be applied to a hole made in the cover for TP models, and in the lead nut for TPR models.

1

2

3

Centralized lubrication

33

lubrication

Many automatic lubrication systems with a central pump and various distribution points are also possible. The amount of lubricant required depends on the duty and work environment. A centralized dosing system does not exclude a periodic check of the lubrication conditions in the threaded spindle.

INSTALLATION AND MAINTENANCE Installation The screw jack must be installed in a manner that does not create lateral loads on the threaded spindle. Great care must be taken to ensure that the threaded spindle is orthogonal to the mounting plane, and that the load and threaded spindle are on the same axis. Employing multiple screw jacks to handle the same load (see the mounting schemes section on pages 90-91) requires further verifications: it is critical that the load points, (the end fittings for TP models and the lead nuts for TPR models), are perfectly aligned in order that the load can be uniformly distributed; otherwise the misaligned screw jacks would act as brake or counter-load. Whenever several jacks have to be connected by means of transmission shafts, it is recommended that they be perfectly aligned in order to avoid overloading of the worm screws. It is advisable to use ts capable of absorbing alignment errors but having, at the same time, a rigid torsion necessary to keep the synchronization of the transmission. The assembly or disassembly of the ts or pulleys of worm screw must be carried out by means of tie rods or extractors, using, if necessary, the threaded hole on top of the worm screw; striking or hammering could damage the inner bearings. For heat-shrinking ts or pulleys, we recommend a temperature between 80-100 °C. Installations environments with dust, water, vapors, etc. require precautions to protect the threaded spindle.This can be done by using elastic or rigid protections. The above protections are also used in order to avoid any accidental human with the moving devices. For civil applications it is always advisable to use the safety components.

Preparing for service All UNIMEC’s screw jacks are supplied filled with long lasting lubricant which ensures a perfect lubrication of the worm gear/worm wheel group and all the inner parts. All screw jacks (except for the size 183) are equipped with a lubricant plug for filling-up the lubricant as necessary. As clearly explained on relative paragraph, lubrication of the threaded spindle is a ’s responsibility and must be carried out periodically depending on the duty conditions and the operating environment. Special systems are available for holding the screw jacks in any position without creating leakage problems. The application of some accessories can limit these assembly possibilities: the various solutions to be adopted will be explained in the relevant paragraphs.

Start-up All screw jacks undergo a careful quality examination before being delivered to the client, and are dynamically tested load-free. When starting-up a machine where screw jacks are installed, it is critical to check for the lubrication of the threaded spindles and for the absence of foreign material. During the calibration phase of the electrical end-of-stroke systems, the inertia of the moving masses should be taken into , which for vertical loads will be lower in ascent and greater in descent. It is advisable to startup the machine with the minimum possible load and to make sure all components are working properly, before assuming regular operation. Especially at start-up, it is critical to follow the instructions given in the manual: continuous or hazardous testing maneuvers could lead to an abnormal overheating of the screw jacks and cause irreparable damages. One single temperature peak is enough to cause premature wear or breakdown of the screw jack.

34

Routine maintenance Screw jacks must be periodically inspected, depending on the level of use and working environment. It is advisable to check for lubricant leakages from the casing, and, if this occurs, it is necessary to find and eliminate the cause and fill the lubricant up the correct level. The lubrication conditions of the threaded spindle must be periodically inspected (and restored if necessary) as well as the presence of any foreign material. The safety components must be inspected according to the applicable norms.

Storage Screw jacks must be protected from deposits of dust and foreign matter during storage. Particular attention must be paid to saline or corrosive atmospheres. We also recommend to: 1 - Periodically rotate the input shaft to ensure proper lubrication of the inner parts and avoid that the seals dry up, therefore causing lubricant leakages. 2 - Lubricate and protect the threaded spindle, the worm screw and the non varnished components. 3 - the threaded spindle in case of horizontal storage.

Warranty Warranty is valid given when the instructions contained in our manual are carefully followed.

ORDERING CODES 306

1/5

1000

size

reduction ratio

stroke [mm]

TF

PR-PE

B

IEC 80B5

SU-PO

motor flange

accessories

end fitting protections construction model

35

installation and maintenance

TP model (TP/TPR) (MTP/MTPR)

TP MODEL 1 2 3 4 5 5.1 6 8 8.1 9 10 11 12 13 13.1 14 14.1 15 16 17 18 19 20 21 22 23

21

Casing Cover Guide bushing Worm wheel Worm screw Motor worm screw right-handed Threaded spindle Worm screw bearing Motor worm screw bearing Worm wheel bearings Seal Seal Seal Snap ring Snap ring for motoring Seal Seal for motoring Rigid protection Key 14 Dowel 13 End fitting elastic fastening pin Plug Elastic protection End fitting Motor flange 17 Screws

18 6 20

2 12

10 9

4

9

8

19

22

16 17

1

16

23

10 5.1

11 16 3

8.1

5

13.1 14.1 8 13 15

36

14

TPR MODEL 6

Casing Cover Guide bushing Worm wheel Worm screw Motor worm screw right handed Threaded spindle Lead nut Worm screw bearing Motor worm screw bearing Worm wheel bearing Seal Seal Seal Snap ring Snap ring for motoring Seal Seal for motoring Key Dowel Worm wheel elastic fastening pin Plug Elastic protection Motor flange Screws Seal

7

20

2 12 10 9

4 18.1

18.1 9 19

22

14 13 8

17

1 2 3 4 5 5.1 6 7 8 8.1 9 10 11 12 13 13.1 14 14.1 16 17 18.1 19 20 22 23 24

16 17

10

23

16

8.1 13.1

11

14.1

16 8

3

13 24

5

14

37

exploded views and spare parts

5.1

1

DIMENSIONING OF THE SCREW JACK For a correct dimensioning of the screw jack it is necessary to observe the following steps: Definition of the application data (A)

Calculation of the unit load (B)

Verification at the equivalent load (C)

negative

Change the size or mounting scheme

positive

Verification at the equivalent power (D)

negative

positive

Verification at the buckling load (E)

negative

positive

Verification at the lateral load (F)

negative

positive

Verification at the torque (G)

negative

positive

Verification at the radial loads (H)

negative

positive

End

DESCRIPTIVE TABLE

38

Taille Size Portée issible issibile load [daN] [daN] Tige Trapezoidal trapézoïdale: spindle: diamètre diameter x pas per[mm] pitch [mm] Rapport Theoretical de réduction reduction théorique ratio rapide Fast Normal normal Slow lent Rapport Real reduction de réduction ratio réelle rapide Fast Normal normal Slow lent Spindle Course tige stroke pour foruna tour turn de of the la roue worm hélicoïdale wheel [mm] [mm] Course tige Spindle stroke pour foruna tour turn de of the la vis worm sansscrew fin [mm] [mm] rapide Fast Normal normal Slow lent Rendement Running efficiency [%] [%] rapide Fast Normal normal Slow lent Operation Température temperature d'exercice[°C] [°C] Weight Poids visoftrapézoïdale the trapezoidal pourscrew 100 for mm100 [kg]mm [kg] Weight Poids vérin of the (sans screw vis)jack [kg](screw not included) [kg]

183 204 306 407 559 7010 8010 500 1000 2500 5000 10000 20000 25000 18x3 20x4 30x6 40x7 55x9 70x10 80x10 1/5 1/5 1/5 1/5 1/5 1/5 1/5 1/20 1/10 1/10 1/10 1/10 1/10 1/10 1/30 1/30 1/30 1/30 1/30 1/30 4/20 4/19 4/19 6/30 6/30 5/26 5/26 1/20 2/21 3/29 3/30 3/30 3/29 3/29 1/30 1/30 1/30 1/30 1/30 1/30 3 4 6 7 9 10 10 0,6 0,8 1,2 1,4 1,8 2,0 2,0 0,15 0,4 0,6 0,7 0,9 1,0 1,0 0,13 0,2 0,23 0,3 0,33 0,33 29 31 30 28 25 23 22 24 28 26 25 22 21 20 20 18 18 17 14 14 -10 / 80 (for different conditions please our technical office) 0,16 0,22 0,5 0,9 1,8 2,8 3,7 1,8 5,9 10 18 34 56 62

A - THE APPLICATION DATA For a right dimensioning of the screw jacks it is necessary to identify the application data: LOAD [daN] = the load is identified with the force applied to the translating device of a screw jack. Normally the dimensioning is calculated considering the maximum applicable load (worst case). It is important to consider the load as a vector, which is defined by a modulus, a direction and a sense: the modulus quantifies the force, the direction orients spatially and gives indications on the eccentricity or on possible lateral loads, the sense identifies the traction or compression load. TRANSLATION SPEED [mm/min] = the translation speed is the load handling speed. From this speed it is possible to calculate the rotation speed of the rotating devices and the necessary power for the movement. Wear phenomena and the life of the screw jack proportionally depend on the value of the translation speed. Therefore, it is advisable to limit the translation speed in a way not to exceed the input speed of 1500 rpm on the worm screw. Input speeds up to 3000 rpm are possible but in such case we suggest ing our technical office. STROKE [mm] = it is the linear measure used to handle a load. It does not always coincide with the total length of the threaded spindle. AMBIENT VARIABLES = these values identify the environment and the operating conditions of the screw jack. Among them: temperature, oxidizing and corrosive factors, working and non-working periods, vibrations, maintenance and cleaning, lubrication quality and quantity etc. MOUNTING SCHEMES = There are several ways of handling a load by means of screw jacks. The schemes on pages 90-91 will show you some examples. Choosing a mounting scheme will condition the choice for the size and the power which is necessary for the application.

B - THE UNIT LOAD AND THE DESCRIPTIVE TABLES According to the n number of screw jacks contained in the mounting scheme it is possible to calculate each screw jack’s load by dividing the total load by n. In case the load is not fairly distributed in all screw jacks, it is recommended to consider the transmission having the heaviest load, by virtue of a dimensioning based on the worst case.

10012 40000 100x12 1/10 1/30 3/31 1/30 12 1,2 0,4 18 12

12014 60000 120x14 1/10 1/30 3/31 1/30 14 1,4 0,47 17 11

14014 80000 140x14 1/12 1/36 3/36 1/36 14 1,16 0,38 16 10

16016 100000 160x16 1/12 1/36 3/36 1/36 16 1,33 0,44 15 9

20018 150000 200x18 1/12 1/36 3/36 1/36 18 1,5 0,5 14 9

5,6 110

5,6 180

8,1 180

11 550

14 550

22 2100

25022 200000 250x22 1/12 1/36 3/36 1/36 22 1,83 0,61 14 9

Size Taille issible load [daN] Portée issibile Trapezoidal spindle: diameter per xpitch Tige trapézoïdale : diamètre pas [mm] Theoretical reduction ratio Rapport de réduction théorique

Fast rapide Normal normal Slow lent Fast Real rapide Rapport de reduction réduction ration réelle Normal normal Slow lent Spindle a turn wheel [mm] Course tigestroke pour for un tour deoflathe roueworm hélicoïdale Spindle turn un of the screw rapide stroke Coursefor tigea pour tourworm de la vis sansfast fin [mm] [mm] Normal normal Slow lent Fast RunningRendement efficiency [%] rapide Normal normal Slow lent Operation temperature Température d'exercice [°C] 35 Weight of the trapezoidal screwpour for 100 mm [kg] Poids vis trapézoïdale 2100 Weight of the screw jackPoids (screw not (sans included) vérin vis) [kg]

39

dimensioning

9010 35000 100x12 1/10 1/30 3/30 1/30 12 1,2 0,4 18 12

C – THE EQUIVALENT LOAD All the values listed in the catalogue refer to standard use conditions, i.e. under a temperature of 20 °C and working percentage of 10%. For different operation conditions the equivalent load should be calculated: it refers to the load which would be applied in standard conditions in order to have the same thermal exchange and wear effects, which the real load achieves in the real conditions of use. It is therefore advisable to calculate the equivalent load according to the following formula: Ce = C•ft•fa•fs

The temperature factor ft

By means of the following diagram an ft factor can be calculated according to the ambient temperature. In case of temperatures higher than 80 °C we suggest ing our technical office.

3

temperature factor ft

2,5 2 1,5 1 0,5 0 10

20

30

40

50

60

70

80

temperature [°C]

The ambient factor fa

By means of the following table it is possible to calculate the fa factor according to the operation conditions. Type of load Light shocks, few insertions, regular movements Medium shocks, frequent insertions, regular movements High shocks, many insertions, irregular movements

40

Ambient factor fa 1 1,2 1,8

The service factor fs The service factor fs is obtained by evaluating the working cycle and calculating the operation percentage on that interval. For example a working time of 10 minutes and non working time of 10 minutes correspond to 50%; similarly a working time of 5 minutes and a non working time of 20 minutes correspond to 20%. Based on the working data, choosing the cycle time and the operation percentage it is possible to read the fs value on the ordinate axis.

service factor fs

5 4,5 4 3,5 3 2,5 2 1,5 1 0,5 0 5

10

20

30

50

75

100

Working percentage [%]

With the aid of the descriptive tables it is possible to check whether the previously chosen size is able to an issible dynamic load equal to the equivalent load. If not, it is necessary to effect a second choice.

D – THE POWER TABLES AND THE EQUIVALENT POWER The power tables are listed from page 46 to page 59. Choosing the tables referring to the size selected in paragraph C and putting the equivalent load values as well as the translation speed values in the table, it is possible to obtain the equivalent power Pe value. If the crossing values fall into the coloured area, this means that the application conditions could cause negative phenomena such as overheating and strong wear. It is therefore necessary to reduce the translation speed or to increase the size.

41

dimensioning

The equivalent power is not the power requested by the single screw jack, unless the three correction factors ft, fa and fs have a unit value.

E – BUCKLING In case of compression load, even occasional, it is necessary to check the buckling structure. Firstly the two constraints which the screw jack have to be determined: the first one is on the end fitting for TP models and on the lead nut for TPR models, while the second one is the way the casing is grounded. Most part of the real cases can be schematized according to three models, as listed below: End fitting – lead nut

Screw jack

Free Hinge Sleeve

Fitted in Hinge Fitted in

Euler I Euler II Euler III

Once the Euler case has been determined which most fits to the current application, it is necessary to find in the corresponding diagram the point corresponding to the coordinates (length; load). The sizes suited to the application are those whose curves subtend the above point. In case the size chosen at paragraph D does not meet such requisites it is necessary to choose a higher size. The Euler-Gordon-Rankine curves have been calculated with a factor of safety equal to 4. For applications which can factors of safety lower than 4 we suggest ing our technical office. EULER 1

EULER 1

10.000

EULER 1

100.000

559 407 7010 8010

306

10.000

Maximum buckling load [daN]

EULER 2

Maximum buckling load [daN]

1.000 204

183

100 0

250

500

750

1000

1250

Spindle length [mm]

EULER 1

180.000

EULER 3

160.000 140.000 120.000 25022

Maximum buckling load [daN]

100.000 20018

80.000 14014

60.000 40.000 20.000 0 0

42

16016

1000

2000

Spindle length [mm]

3000

4000

5000

6000

12014

1.000 0

250 500 750 1000 1250 1500 1750 2000 2250 2500 2750

Spindle length [mm]

200.000

9010 10012

EULER 2

10.000

EULER 3

10.000

559

559

407

407

1.000 Maximum buckling load [daN]

Maximum buckling load [daN]

306

306

1.000 204 183

100 0

250

500

204 183

100

750 1000 1250 1500 1750 2000 2250

0

Spindle length [mm]

500

1000

1500

2000

2500

3000

Spindle length [mm]

EULER 3

EULER 2 100.000

100.000

12014

7010

10012

1.000

500 1000 1500 2000 2500 3000 3500 4000 4500 5000

0

Spindle length [mm]

500 1000 1500 2000 2500 3000 3500 4000 4500 5000 5500 6000

Spindle length [mm]

EULER 2 200.000

200.000

180.000

180.000

EULER 3

25022

25022

160.000

140.000

140.000

120.000

120.000

20018

20018

100.000

80.000 14014

60.000

Maximum buckling load [daN]

100.000

16016

40.000 20.000 0 0

1000

2000

Spindle length [mm]

3000

4000

5000

6000

16016

80.000 14014

60.000 40.000 20.000 0 0

1000

2000

Spindle length [mm]

3000

4000

5000

6000

43

dimensioning

160.000

Maximum buckling load [daN]

10012

10.000

1.000 0

8010

7010

Maximum buckling load [daN]

Maximum buckling load [daN]

10.000

9010

12014

9010

8010

F – THE LATERAL LOAD As stated in the previous paragraphs lateral loads are the main cause of failures. In addition to the misalignment of the threaded spindle and the load, they can be caused by inaccurate mountings which force the threaded spindle in an anomalous position. As a consequence the coupling between lead nut and threaded spindle for TPR model and between the threaded spindle and the worm wheel for the TP model will be wrong.The application of double serial guides allows, for TP models, a partial correction of the anomalous position of the threaded spindle before ing the worm wheel. The problem is transformed into a sliding of the threaded spindle on the guides themselves. In TPR model, it is the outer nut which s the threaded spindle and it is therefore not possible to apply any corrections, unless particular mountings are applied as illustrated in the paragraph “lateral backlash in TPR models”. Lateral loads can even derive from an horizontal mounting: the threaded spindle own weight causes a bending of the same, becoming in this way a lateral load. The border value for the bending and the consequent lateral load depends on the screw jack size and on the threaded spindle length. It is advisable to our technical office in order to foresee the suitable s. The following diagrams, which are valid for static loads, show the issible lateral load value, according to the size and the length of the threaded spindle. For dynamic applications it is necessary to ask to the technical office.

maximum static lateral load [daN]

1.000

100 559

407

306

10

204

183

1

0

500

1000

1500

2000

spindle length [mm]

maximum static lateral load [daN]

10.000

14014

1.000

16016

25022

20018

12014

100

8010

7010

0

500

1000

9010 10012

1500

2000

spindle length [mm]

In case the size chosen in the previous paragraphs is not enough to a particular lateral load, a suitable size should be chosen.

G – THE TORQUE At this stage it is possible to calculate the power requested by the mounting. The following formula will be used to calculate this value: P=

1 n•C•v • 1000 6000•ηm•ηc•ηs

where: P = n = C = v = ηm = ηc = η 44 s =

requested power [kW] number of screw jacks unit load [daN] translation speed [mm/min] screw jack running efficiency (see descriptive tables) configuration running efficiency = 1 - [(N-1) • 0,05], where N is the total number of screw jacks and gear boxes structure running efficiency (guides, belts, pulleys, shafts, ts, reducers)

In order to complete the calculation of the requested power it is necessary to calculate the torque which should be transmitted by the drive shaft: Mtm =

955•P ωm

where: Mtm = is the torque on the drive shaft [daNm] P = is the motor power [kW] ωm = is the angular speed of the motor [rpm]

According to the applied mounting scheme it is necessary to check that the worm screw will be able to hold out under a possible combined torque. In the following table the issible torque values are listed for the worm screws according to their size and expressed as [daNm].

Size 183 Fast ratio [daNm] 2,30 Normal ratio [daNm] 2,30 Slow ratio [daNm] -

204 5,43 5,43 4,18

306 6,90 15,4 18,3

407 49,0 12,8 15,4

559 49,0 12,8 15,4

7010 84,7 84,7 49,0

8010 84,7 84,7 49,0

9010 10012 12014 14014 16016 20018 25022 202 522 522 823 823 2847 2847 202 441 441 984 984 2847 2847

In case the above values are exceeded it will be necessary to choose a higher size, to change the mounting scheme or to increase the speed, in accordance to what has been indicated in the previous paragraphs.

H - RADIAL LOADS

Size Frv [daN]

183 10

204 22

306 45

407 60

559 60

7010 90

8010 90

9010 10012 12014 14014 16016 20018 25022 100 250 250 300 300 380 380

In case the above values are exceeded it will be necessary to choose a higher size, to change the mounting scheme or to increase the speed, in accordance to what has been indicated in the previous paragraphs. 45

dimensioning

In case of radial loads on the worm screw it is necessary to check their strength according to the following table:

Size 183 Ratio 1/5 Load [daN] Worm screw rotation speed ωv [rpm] 1500 1000 750 500 300 100 50

Threaded spindle translation speed v [mm/min] 900 600 450 300 180 60 30

500

400

300

200

100

50

Pi Mtv [kW] [daNm]

Pi Mtv [kW] [daNm]

Pi Mtv [kW] [daNm]

Pi Mtv [kW] [daNm]

Pi Mtv [kW] [daNm]

Pi Mtv [kW] [daNm]

0,25 0,17 0,13 0,09 0,07 0,07 0,07

0,21 0,14 0,10 0,07 0,07 0,07 0,07

0,15 0,10 0,08 0,07 0,07 0,07 0,07

0,10 0,07 0,07 0,07 0,07 0,07 0,07

0,07 0,07 0,07 0,07 0,07 0,07 0,07

0,07 0,07 0,07 0,07 0,07 0,07 0,07

0,17 0,17 0,17 0,17 0,17 0,17 0,17

0,14 0,14 0,14 0,14 0,14 0,14 0,14

0,10 0,10 0,10 0,10 0,10 0,10 0,10

0,07 0,07 0,07 0,07 0,07 0,07 0,07

0,03 0,03 0,03 0,03 0,03 0,03 0,03

0,03 0,03 0,03 0,03 0,03 0,03 0,03

Ratio 1/20 Load [daN] Worm screw rotation speed ωv [rpm] 1500 1000 750 500 300 100 50

46

Threaded spindle translation speed v [mm/min] 225 150 112,5 75 45 15 7,5

500

400

300

200

100

50

Pi Mtv [kW] [daNm]

Pi Mtv [kW] [daNm]

Pi Mtv [kW] [daNm]

Pi Mtv [kW] [daNm]

Pi Mtv [kW] [daNm]

Pi Mtv [kW] [daNm]

0,08 0,07 0,07 0,07 0,07 0,07 0,07

0,07 0,07 0,07 0,07 0,07 0,07 0,07

0,07 0,07 0,07 0,07 0,07 0,07 0,07

0,07 0,07 0,07 0,07 0,07 0,07 0,07

0,07 0,07 0,07 0,07 0,07 0,07 0,07

0,07 0,07 0,07 0,07 0,07 0,07 0,07

0,06 0,06 0,06 0,06 0,06 0,06 0,06

0,05 0,05 0,05 0,05 0,05 0,05 0,05

0,04 0,04 0,04 0,04 0,04 0,04 0,04

0,04 0,04 0,04 0,04 0,04 0,04 0,04

0,04 0,04 0,04 0,04 0,04 0,04 0,04

0,04 0,04 0,04 0,04 0,04 0,04 0,04

Size 204 Ratio 1/5 Load [daN] Worm Threaded screw spindle rotation translation speed speed ωv [rpm] v [mm/min] 1500 1200 1000 800 750 600 500 400 300 240 100 80 50 40

1000 Pi Mtv [kW] [daNm]

0,64 0,43 0,32 0,21 0,13 0,07 0,07

0,42 0,42 0,42 0,42 0,42 0,42 0,42

800 Pi Mtv [kW] [daNm]

600 Pi Mtv [kW] [daNm]

400 Pi Mtv [kW] [daNm]

300 Pi Mtv [kW] [daNm]

200 Pi Mtv [kW] [daNm]

100 Pi Mtv [kW] [daNm]

0,51 0,34 0,26 0,17 0,11 0,07 0,07

0,38 0,26 0,19 0,13 0,11 0,07 0,07

0,26 0,17 0,13 0,09 0,07 0,07 0,07

0,19 0,13 0,10 0,07 0,07 0,07 0,07

0,13 0,09 0,07 0,07 0,07 0,07 0,07

0,07 0,07 0,07 0,07 0,07 0,07 0,07

0,33 0,33 0,33 0,33 0,33 0,33 0,33

0,25 0,25 0,25 0,25 0,25 0,25 0,25

0,17 0,17 0,17 0,17 0,17 0,17 0,17

0,13 0,13 0,13 0,13 0,13 0,13 0,13

0,09 0,09 0,09 0,09 0,09 0,09 0,09

0,05 0,05 0,05 0,05 0,05 0,05 0,05

Ratio 1/10 Load [daN] Worm Threaded screw spindle rotation translation speed speed ωv [rpm] v [mm/min] 1500 600 1000 400 750 300 500 200 300 120 100 40 50 20

1000 Pi Mtv [kW] [daNm]

800

600

Pi Mtv [kW] [daNm]

Pi Mtv [kW] [daNm]

400 Pi Mtv [kW] [daNm]

300 Pi Mtv [kW] [daNm]

200 Pi Mtv [kW] [daNm]

100 Pi Mtv [kW] [daNm]

0,36 0,24 0,18 0,12 0,07 0,07 0,07

0,30 0,20 0,15 0,10 0,07 0,07 0,07

0,22 0,14 0,11 0,07 0,07 0,07 0,07

0,14 0,09 0,07 0,07 0,07 0,07 0,07

0,11 0,07 0,07 0,07 0,07 0,07 0,07

0,08 0,07 0,07 0,07 0,07 0,07 0,07

0,07 0,07 0,07 0,07 0,07 0,07 0,07

0,23 0,23 0,23 0,23 0,23 0,23 0,23

0,19 0,19 0,19 0,19 0,19 0,19 0,19

0,14 0,14 0,14 0,14 0,14 0,14 0,14

0,09 0,09 0,09 0,09 0,09 0,09 0,09

0,07 0,07 0,07 0,07 0,07 0,07 0,07

0,05 0,05 0,05 0,05 0,05 0,05 0,05

0,03 0,03 0,03 0,03 0,03 0,03 0,03

Ratio 1/30 Load [daN]

1000

800

600

400

300

200

Worm Threaded screw spindle rotation translation speed speed ωv [rpm] v [mm/min] 1500 200 1000 133 750 100 500 67 300 40 100 13 50 6,7

Pi Mtv [kW] [daNm]

Pi Mtv [kW] [daNm]

Pi Mtv [kW] [daNm]

Pi Mtv [kW] [daNm]

Pi Mtv [kW] [daNm]

Pi Mtv [kW] [daNm]

Pi Mtv [kW] [daNm]

0,17 0,12 0,08 0,07 0,07 0,07 0,07

0,13 0,08 0,07 0,07 0,07 0,07 0,07

0,11 0,07 0,07 0,07 0,07 0,07 0,07

0,07 0,07 0,07 0,07 0,07 0,07 0,07

0,07 0,07 0,07 0,07 0,07 0,07 0,07

0,07 0,07 0,07 0,07 0,07 0,07 0,07

0,07 0,07 0,07 0,07 0,07 0,07 0,07

0,08 0,08 0,08 0,08 0,08 0,08 0,08

0,07 0,07 0,07 0,07 0,07 0,07 0,07

0,05 0,05 0,05 0,05 0,05 0,05 0,05

0,03 0,03 0,03 0,03 0,03 0,03 0,03

0,03 0,03 0,03 0,03 0,03 0,03 0,03

0,03 0,03 0,03 0,03 0,03 0,03 0,03

47

power tables

0,11 0,11 0,11 0,11 0,11 0,11 0,11

100

Size 306 Ratio 1/5 Load [daN] Worm Threaded screw spindle rotation translation speed speed ωv [rpm] v [mm/min] 1500 1800 1000 1200 750 900 500 600 300 360 100 120 50 60

2500 Pi Mtv [kW] [daNm]

2000 Pi Mtv [kW] [daNm]

1500 Pi Mtv [kW] [daNm]

1000 Pi Mtv [kW] [daNm]

750 Pi Mtv [kW] [daNm]

500 Pi Mtv [kW] [daNm]

250 Pi Mtv [kW] [daNm]

2,45 1,64 1,23 0,82 0,49 0,17 0,10

1,96 1,31 0,98 0,66 0,40 0,13 0,10

1,47 0,98 0,74 0,49 0,30 0,10 0,10

0,98 0,65 0,49 0,33 0,20 0,10 0,10

0,74 0,49 0,37 0,25 0,15 0,10 0,10

0,49 0,33 0,25 0,17 0,10 0,10 0,10

0,25 0,17 0,13 0,10 0,10 0,10 0,10

1,60 1,60 1,60 1,60 1,60 1,60 1,60

1,28 1,28 1,28 1,28 1,28 1,28 1,28

0,96 0,96 0,96 0,96 0,96 0,96 0,96

0,64 0,64 0,64 0,64 0,64 0,64 0,64

0,48 0,48 0,48 0,48 0,48 0,48 0,48

0,32 0,32 0,32 0,32 0,32 0,32 0,32

0,17 0,17 0,17 0,17 0,17 0,17 0,17

Ratio 1/10 Load [daN] Worm Threaded screw spindle rotation translation speed speed ωv [rpm] v [mm/min] 1500 900 1000 600 750 450 500 300 300 180 100 60 50 30

2500 Pi Mtv [kW] [daNm]

2000 Pi Mtv [kW] [daNm]

1500 Pi Mtv [kW] [daNm]

1000 Pi Mtv [kW] [daNm]

750 Pi Mtv [kW] [daNm]

500 Pi Mtv [kW] [daNm]

250 Pi Mtv [kW] [daNm]

1,43 0,96 0,72 0,48 0,28 0,10 0,10

1,14 0,76 0,57 0,38 0,23 0,10 0,10

0,86 0,58 0,43 0,28 0,18 0,10 0,10

0,57 0,38 0,29 0,19 0,12 0,10 0,10

0,43 0,29 0,22 0,15 0,10 0,10 0,10

0,29 0,20 0,15 0,10 0,10 0,10 0,10

0,16 0,10 0,10 0,10 0,10 0,10 0,10

0,93 0,93 0,93 0,93 0,93 0,93 0,93

0,74 0,74 0,74 0,74 0,74 0,74 0,74

0,56 0,56 0,56 0,56 0,56 0,56 0,56

0,37 0,37 0,37 0,37 0,37 0,37 0,37

0,28 0,28 0,28 0,28 0,28 0,28 0,28

0,19 0,19 0,19 0,19 0,19 0,19 0,19

0,10 0,10 0,10 0,10 0,10 0,10 0,10

Ratio 1/30 Load [daN] Worm Threaded screw spindle rotation translation speed speed ωv [rpm] v [mm/min] 1500 300 1000 200 750 150 500 100 300 60 100 20 50 10

48

2500 Pi Mtv [kW] [daNm]

2000 Pi Mtv [kW] [daNm]

1500 Pi Mtv [kW] [daNm]

1000 Pi Mtv [kW] [daNm]

750 Pi Mtv [kW] [daNm]

500 Pi Mtv [kW] [daNm]

250 Pi Mtv [kW] [daNm]

0,68 0,45 0,34 0,23 0,14 0,07 0,07

0,56 0,37 0,28 0,19 0,11 0,11 0,11

0,42 0,28 0,21 0,14 0,08 0,08 0,08

0,28 0,19 0,14 0,10 0,07 0,07 0,07

0,22 0,14 0,11 0,07 0,07 0,07 0,07

0,14 0,10 0,07 0,07 0,07 0,07 0,07

0,07 0,07 0,07 0,07 0,07 0,07 0,07

0,44 0,44 0,44 0,44 0,44 0,44 0,44

0,36 0,36 0,36 0,36 0,36 0,36 0,36

0,27 0,27 0,27 0,27 0,27 0,27 0,27

0,18 0,18 0,18 0,18 0,18 0,18 0,18

0,14 0,14 0,14 0,14 0,14 0,14 0,14

0,09 0,09 0,09 0,09 0,09 0,09 0,09

0,05 0,05 0,05 0,05 0,05 0,05 0,05

Size 407 Ratio 1/5 Load [daN] Worm Threaded screw spindle rotation translation speed speed ωv [rpm] v [mm/min] 1500 2100 1000 1400 750 1050 500 700 300 420 100 140 50 70

5000 Pi Mtv [kW] [daNm]

4000 Pi Mtv [kW] [daNm]

3000 Pi Mtv [kW] [daNm]

2000 Pi Mtv [kW] [daNm]

1500 Pi Mtv [kW] [daNm]

1000 Pi Mtv [kW] [daNm]

500 Pi Mtv [kW] [daNm]

6,13 4,09 3,06 2,04 1,23 0,41 0,21

4,90 3,27 2,45 1,64 0,98 0,33 0,17

3,68 2,15 1,80 1,23 0,74 0,25 0,13

2,45 1,64 1,23 0,82 0,49 0,17 0,10

1,84 1,23 0,92 0,62 0,37 0,13 0,10

1,23 0,82 0,62 0,41 0,25 0,10 0,10

0,62 0,41 0,31 0,21 0,13 0,10 0,10

3,98 3,98 3,98 3,98 3,98 3,98 3,98

3,18 3,18 3,18 3,18 3,18 3,18 3,18

2,39 2,39 2,39 2,39 2,39 2,39 2,39

1,59 1,59 1,59 1,59 1,59 1,59 1,59

1,20 1,20 1,20 1,20 1,20 1,20 1,20

0,80 0,80 0,80 0,80 0,80 0,80 0,80

0,40 0,40 0,40 0,40 0,40 0,40 0,40

Ratio 1/10 Load [daN] Worm Threaded screw spindle rotation translation speed speed ωv [rpm] v [mm/min] 1500 1050 1000 700 750 525 500 350 300 210 100 70 50 35

5000 Pi Mtv [kW] [daNm]

4000 Pi Mtv [kW] [daNm]

3000 Pi Mtv [kW] [daNm]

2000 Pi Mtv [kW] [daNm]

1500 Pi Mtv [kW] [daNm]

1000 Pi Mtv [kW] [daNm]

500 Pi Mtv [kW] [daNm]

3,60 2,40 1,77 1,18 0,71 0,24 0,12

2,80 1,85 1,40 0,92 0,56 0,19 0,10

2,10 1,38 1,00 0,69 0,42 0,14 0,10

1,40 0,92 0,70 0,46 0,28 0,10 0,10

1,05 0,69 0,52 0,35 0,21 0,10 0,10

0,70 0,46 0,35 0,23 0,14 0,10 0,10

0,35 0,23 0,18 0,12 0,10 0,10 0,10

2,30 2,30 2,30 2,30 2,30 2,30 2,30

1,80 1,80 1,80 1,80 1,80 1,80 1,80

1,34 1,34 1,34 1,34 1,34 1,34 1,34

0,90 0,90 0,90 0,90 0,90 0,90 0,90

0,67 0,67 0,67 0,67 0,67 0,67 0,67

0,45 0,45 0,45 0,45 0,45 0,45 0,45

0,23 0,23 0,23 0,23 0,23 0,23 0,23

Ratio 1/30 5000 Pi Mtv [kW] [daNm]

4000 Pi Mtv [kW] [daNm]

3000 Pi Mtv [kW] [daNm]

2000 Pi Mtv [kW] [daNm]

1500 Pi Mtv [kW] [daNm]

1000 Pi Mtv [kW] [daNm]

500 Pi Mtv [kW] [daNm]

1,69 1,13 0,85 0,56 0,34 0,12 0,07

1,26 0,84 0,63 0,42 0,25 0,08 0,07

0,95 0,64 0,48 0,32 0,19 0,07 0,07

0,63 0,42 0,32 0,21 0,13 0,07 0,07

0,48 0,32 0,24 0,16 0,10 0,07 0,07

0,32 0,21 0,16 0,11 0,07 0,07 0,07

0,17 0,11 0,08 0,07 0,07 0,07 0,07

1,10 1,10 1,10 1,10 1,10 1,10 1,10

0,82 0,82 0,82 0,82 0,82 0,82 0,82

0,62 0,62 0,62 0,62 0,62 0,62 0,62

0,41 0,41 0,41 0,41 0,41 0,41 0,41

0,31 0,31 0,31 0,31 0,31 0,31 0,31

0,21 0,21 0,21 0,21 0,21 0,21 0,21

0,11 0,11 0,11 0,11 0,11 0,11 0,11

49

power tables

Load [daN] Worm Threaded screw spindle rotation translation speed speed ωv [rpm] v [mm/min] 1500 350 1000 233 750 175 500 117 300 70 100 23 50 11,7

Size 559 Ratio 1/5 Load [daN] Worm Threaded screw spindle rotation translation speed speed ωv [rpm] v [mm/min] 1500 2700 1000 1800 750 1350 500 900 300 540 100 180 50 90

10000 Pi Mtv [kW] [daNm]

7500 Pi Mtv [kW] [daNm]

5000 Pi Mtv [kW] [daNm]

4000 Pi Mtv [kW] [daNm]

3000 Pi Mtv [kW] [daNm]

2000 Pi Mtv [kW] [daNm]

1000 Pi Mtv [kW] [daNm]

17,7 11,8 8,83 5,88 3,53 1,18 0,57

13,3 8,83 6,62 4,42 2,65 0,88 0,44

8,83 5,89 4,42 2,94 1,77 0,59 0,30

7,06 4,71 3,53 2,36 1,42 0,47 0,24

5,30 3,53 2,65 1,77 1,06 0,36 0,18

3,53 2,36 1,77 1,18 0,71 0,24 0,12

1,77 1,18 0,89 0,59 0,36 0,12 0,10

11,5 11,5 11,5 11,5 11,5 11,5 11,5

8,60 8,60 8,60 8,60 8,60 8,60 8,60

5,74 5,74 5,74 5,74 5,74 5,74 5,74

4,58 4,58 4,58 4,58 4,58 4,58 4,58

3,44 3,44 3,44 3,44 3,44 3,44 3,44

2,29 2,29 2,29 2,29 2,29 2,29 2,29

1,15 1,15 1,15 1,15 1,15 1,15 1,15

Ratio 1/10 Load [daN] Worm Threaded screw spindle rotation translation speed speed ωv [rpm] v [mm/min] 1500 1350 1000 900 750 675 500 450 300 270 100 90 50 45

10000 Pi Mtv [kW] [daNm]

7500 Pi Mtv [kW] [daNm]

5000 Pi Mtv [kW] [daNm]

4000 Pi Mtv [kW] [daNm]

3000 Pi Mtv [kW] [daNm]

2000 Pi Mtv [kW] [daNm]

1000 Pi Mtv [kW] [daNm]

10,0 6,70 5,00 3,30 2,00 0,67 0,33

7,50 5,00 3,77 2,50 1,50 0,50 0,25

5,00 3,40 2,50 1,67 1,00 0,33 0,17

4,00 2,70 2,00 1,33 0,80 0,27 0,13

3,10 2,10 1,54 1,03 0,62 0,20 0,10

2,00 1,35 1,00 0,67 0,40 0,13 0,10

1,00 0,67 0,50 0,33 0,20 0,10 0,10

6,50 6,50 6,50 6,50 6,50 6,50 6,50

4,90 4,90 4,90 4,90 4,90 4,90 4,90

3,25 3,25 3,25 3,25 3,25 3,25 3,25

2,60 2,60 2,60 2,60 2,60 2,60 2,60

2,00 2,00 2,00 2,00 2,00 2,00 2,00

1,30 1,30 1,30 1,30 1,30 1,30 1,30

0,65 0,65 0,65 0,65 0,65 0,65 0,65

Ratio 1/30 Load [daN] Worm Threaded screw spindle rotation translation speed speed ωv [rpm] v [mm/min] 1500 450 1000 300 750 225 500 150 300 90 100 30 50 15

50

10000 Pi Mtv [kW] [daNm]

7500 Pi Mtv [kW] [daNm]

5000 Pi Mtv [kW] [daNm]

4000 Pi Mtv [kW] [daNm]

3000 Pi Mtv [kW] [daNm]

2000 Pi Mtv [kW] [daNm]

1000 Pi Mtv [kW] [daNm]

4,30 2,90 2,16 1,44 0,86 0,29 0,14

3,30 2,16 1,62 1,10 0,65 0,22 0,11

2,20 1,44 1,08 0,72 0,43 0,15 0,07

1,73 1,15 0,86 0,58 0,35 0,12 0,07

1,30 0,86 0,65 0,43 0,26 0,09 0,07

0,86 0,58 0,43 0,29 0,18 0,07 0,07

0,43 0,29 0,22 0,15 0,09 0,07 0,07

2,80 2,80 2,80 2,80 2,80 2,80 2,80

2,10 2,10 2,10 2,10 2,10 2,10 2,10

1,40 1,40 1,40 1,40 1,40 1,40 1,40

1,12 1,12 1,12 1,12 1,12 1,12 1,12

0,84 0,84 0,84 0,84 0,84 0,84 0,84

0,56 0,56 0,56 0,56 0,56 0,56 0,56

0,28 0,28 0,28 0,28 0,28 0,28 0,28

Size 7010 Ratio 1/5 Load [daN] Worm Threaded screw spindle rotation translation speed speed ωv [rpm] v [mm/min] 1500 3000 1000 2000 750 1500 500 1000 300 600 100 200 50 100

20000 Pi Mtv [kW] [daNm]

17500 Pi Mtv [kW] [daNm]

15000 Pi Mtv [kW] [daNm]

10000 Pi Mtv [kW] [daNm]

7500 Pi Mtv [kW] [daNm]

5000 Pi Mtv [kW] [daNm]

2500 Pi Mtv [kW] [daNm]

42,6 28,4 21,3 14,2 8,53 2,84 1,42

37,3 24,9 18,7 12,4 7,46 2,49 1,24

32,0 21,3 16,0 10,7 6,39 2,13 1,07

21,3 14,2 10,7 7,10 4,26 1,42 0,71

16,0 10,7 8,00 5,33 3,20 1,07 0,53

10,7 7,10 5,33 3,55 2,13 0,71 0,36

5,33 3,55 2,66 1,78 1,07 0,36 0,18

27,7 27,7 27,7 27,7 27,7 27,7 27,7

24,3 24,3 24,3 24,3 24,3 24,3 24,3

20,8 20,8 20,8 20,8 20,8 20,8 20,8

13,8 13,8 13,8 13,8 13,8 13,8 13,8

10,4 10,4 10,4 10,4 10,4 10,4 10,4

6,95 6,95 6,95 6,95 6,95 6,95 6,95

3,46 3,46 3,46 3,46 3,46 3,46 3,46

Ratio 1/10 Load [daN] Worm Threaded screw spindle rotation translation speed speed ωv [rpm] v [mm/min] 1500 1500 1000 1000 750 750 500 500 300 300 100 100 50 50

20000 Pi Mtv [kW] [daNm]

17500 Pi Mtv [kW] [daNm]

15000 Pi Mtv [kW] [daNm]

10000 Pi Mtv [kW] [daNm]

7500 Pi Mtv [kW] [daNm]

5000 Pi Mtv [kW] [daNm]

2500 Pi Mtv [kW] [daNm]

23,4 15,6 11,7 7,80 4,68 1,56 0,78

20,5 13,7 10,2 6,80 4,10 1,37 0,68

17,6 11,7 8,80 5,90 3,50 1,17 0,58

11,7 7,80 5,90 3,90 2,34 0,78 0,39

8,80 5,90 4,40 2,92 1,75 0,59 0,29

5,86 3,90 2,92 1,95 1,17 0,39 0,20

2,93 1,95 1,46 0,98 0,58 0,20 0,10

15,2 15,2 15,2 15,2 15,2 15,2 15,2

13,3 13,3 13,3 13,3 13,3 13,3 13,3

11,4 11,4 11,4 11,4 11,4 11,4 11,4

7,60 7,60 7,60 7,60 7,60 7,60 7,60

5,70 5,70 5,70 5,70 5,70 5,70 5,70

3,80 3,80 3,80 3,80 3,80 3,80 3,80

1,90 1,90 1,90 1,90 1,90 1,90 1,90

Ratio 1/30 20000 Pi Mtv [kW] [daNm]

17500 Pi Mtv [kW] [daNm]

15000 Pi Mtv [kW] [daNm]

10000 Pi Mtv [kW] [daNm]

7500 Pi Mtv [kW] [daNm]

5000 Pi Mtv [kW] [daNm]

2500 Pi Mtv [kW] [daNm]

11,7 7,80 5,85 3,90 2,34 0,78 0,39

10,3 6,90 5,16 3,44 2,06 0,69 0,34

8,80 5,90 4,40 2,92 1,76 0,59 0,30

5,90 3,90 2,93 1,95 1,17 0,39 0,20

4,50 3,00 2,23 1,49 0,89 0,30 0,14

2,90 2,00 1,46 0,98 0,58 0,20 0,10

1,46 1,00 0,73 0,49 0,29 0,10 0,07

7,60 7,60 7,60 7,60 7,60 7,60 7,60

6,70 6,70 6,70 6,70 6,70 6,70 6,70

5,70 5,70 5,70 5,70 5,70 5,70 5,70

3,80 3,80 3,80 3,80 3,80 3,80 3,80

2,90 2,90 2,90 2,90 2,90 2,90 2,90

1,90 1,90 1,90 1,90 1,90 1,90 1,90

0,95 0,95 0,95 0,95 0,95 0,95 0,95

51

power tables

Load [daN] Worm Threaded screw spindle rotation translation speed speed ωv [rpm] v [mm/min] 1500 500 1000 333 750 250 500 167 300 100 100 33 50 16,7

Size 8010 Ratio 1/5 Load [daN] Worm Threaded screw spindle rotation translation speed speed ωv [rpm] v [mm/min] 1500 3000 1000 2000 750 1500 500 1000 300 600 100 200 50 100

25000 Pi Mtv [kW] [daNm]

20000 Pi Mtv [kW] [daNm]

15000 Pi Mtv [kW] [daNm]

10000 Pi Mtv [kW] [daNm]

7500 Pi Mtv [kW] [daNm]

5000 Pi Mtv [kW] [daNm]

2500 Pi Mtv [kW] [daNm]

55,7 37,2 27,9 18,6 11,2 3,72 1,86

44,6 29,7 22,3 14,9 8,92 2,97 1,49

33,4 22,3 16,7 11,2 6,68 2,23 1,12

22,3 14,9 11,2 7,43 4,46 1,49 0,75

16,7 11,2 6,68 5,57 3,34 1,12 0,56

11,2 7,43 5,57 3,72 2,23 0,75 0,38

5,57 3,72 2,79 1,86 1,12 0,38 0,19

36,2 36,2 36,2 36,2 36,2 36,2 36,2

29,0 29,0 29,0 29,0 29,0 29,0 29,0

21,7 21,7 21,7 21,7 21,7 21,7 21,7

14,5 14,5 14,5 14,5 14,5 14,5 14,5

10,9 10,9 10,9 10,9 10,9 10,9 10,9

7,24 7,24 7,24 7,24 7,24 7,24 7,24

3,62 3,62 3,62 3,62 3,62 3,62 3,62

Ratio 1/10 Load [daN] Worm Threaded screw spindle rotation translation speed speed ωv [rpm] v [mm/min] 1500 1500 1000 1000 750 750 500 500 300 300 100 100 50 50

25000 Pi Mtv [kW] [daNm]

20000 Pi Mtv [kW] [daNm]

15000 Pi Mtv [kW] [daNm]

10000 Pi Mtv [kW] [daNm]

7500 Pi Mtv [kW] [daNm]

5000 Pi Mtv [kW] [daNm]

2500 Pi Mtv [kW] [daNm]

30,8 20,5 15,4 10,3 6,16 2,06 1,02

24,5 16,4 12,3 8,20 4,90 1,65 0,82

18,4 12,3 9,24 6,16 3,70 1,24 0,61

12,3 8,20 6,16 4,10 2,50 0,82 0,41

9,20 6,02 4,62 3,08 1,85 0,62 0,31

6,20 4,10 3,08 2,05 1,23 0,41 0,21

3,10 2,05 1,54 1,03 0,62 0,21 0,11

20,0 20,0 20,0 20,0 20,0 20,0 20,0

16,0 16,0 16,0 16,0 16,0 16,0 16,0

12,0 12,0 12,0 12,0 12,0 12,0 12,0

8,00 8,00 8,00 8,00 8,00 8,00 8,00

6,00 6,00 6,00 6,00 6,00 6,00 6,00

4,00 4,00 4,00 4,00 4,00 4,00 4,00

2,00 2,00 2,00 2,00 2,00 2,00 2,00

Ratio 1/30 Load [daN] Worm Threaded screw spindle rotation translation speed speed ωv [rpm] v [mm/min] 1500 500 1000 333 750 250 500 167 300 100 100 33 50 16,7

52

25000 Pi Mtv [kW] [daNm]

20000 Pi Mtv [kW] [daNm]

15000 Pi Mtv [kW] [daNm]

10000 Pi Mtv [kW] [daNm]

7500 Pi Mtv [kW] [daNm]

5000 Pi Mtv [kW] [daNm]

2500 Pi Mtv [kW] [daNm]

14,5 9,70 7,30 4,80 2,90 0,96 0,48

11,7 7,80 5,85 3,90 2,34 0,78 0,39

8,80 5,90 4,40 2,92 1,76 0,59 0,30

5,90 3,90 2,93 1,95 1,17 0,39 0,20

4,50 3,00 2,23 1,49 0,89 0,30 0,14

2,90 2,00 1,46 0,98 0,58 0,20 0,10

1,46 1,00 0,73 0,49 0,29 0,10 0,07

9,40 9,40 9,40 9,40 9,40 9,40 9,40

7,60 7,60 7,60 7,60 7,60 7,60 7,60

5,70 5,70 5,70 5,70 5,70 5,70 5,70

3,80 3,80 3,80 3,80 3,80 3,80 3,80

2,90 2,90 2,90 2,90 2,90 2,90 2,90

1,90 1,90 1,90 1,90 1,90 1,90 1,90

0,95 0,95 0,95 0,95 0,95 0,95 0,95

Size 9010 Ratio 1/10 Load [daN] Worm Threaded screw spindle rotation translation speed speed ωv [rpm] v [mm/min] 1500 1800 1000 1200 750 900 500 600 300 360 100 120 50 60

35000 Pi Mtv [kW] [daNm]

25000 Pi Mtv [kW] [daNm]

20000 Pi Mtv [kW] [daNm]

15000 Pi Mtv [kW] [daNm]

10000 Pi Mtv [kW] [daNm]

5000 Pi Mtv [kW] [daNm]

57,2 38,2 28,6 19,1 11,5 3,90 1,90

40,8 27,2 20,4 13,6 8,20 2,80 1,40

32,7 21,8 16,4 10,9 6,60 2,20 1,10

24,5 16,4 12,3 8,20 4,90 1,70 0,90

16,4 10,9 8,20 5,50 3,30 1,10 0,60

8,20 5,50 4,10 2,80 1,70 0,60 0,30

37,2 37,2 37,2 37,2 37,2 37,2 37,2

26,5 26,5 26,5 26,5 26,5 26,5 26,5

21,2 21,2 21,2 21,2 21,2 21,2 21,2

15,9 15,9 15,9 15,9 15,9 15,9 15,9

10,6 10,6 10,6 10,6 10,6 10,6 10,6

5,30 5,30 5,30 5,30 5,30 5,30 5,30

Ratio 1/30 35000 Pi Mtv [kW] [daNm]

25000 Pi Mtv [kW] [daNm]

20000 Pi Mtv [kW] [daNm]

15000 Pi Mtv [kW] [daNm]

10000 Pi Mtv [kW] [daNm]

5000 Pi Mtv [kW] [daNm]

28,6 19,1 14,3 9,60 5,80 1,90 1,00

20,4 13,6 10,2 6,90 4,10 1,40 0,70

16,4 10,9 8,20 5,50 3,30 1,10 0,60

12,3 8,20 6,20 4,10 2,50 0,90 0,50

8,20 5,50 4,10 2,80 1,70 0,60 0,30

4,10 2,80 2,10 1,40 0,90 0,30 0,20

18,6 18,6 18,6 18,6 18,6 18,6 18,6

13,3 13,3 13,3 13,3 13,3 13,3 13,3

10,7 10,7 10,7 10,7 10,7 10,7 10,7

8,00 8,00 8,00 8,00 8,00 8,00 8,00

5,40 5,40 5,40 5,40 5,40 5,40 5,40

2,70 2,70 2,70 2,70 2,70 2,70 2,70

53

power tables

Load [daN] Worm Threaded screw spindle rotation translation speed speed ωv [rpm] v [mm/min] 1500 600 1000 400 750 300 500 200 300 120 100 40 50 20

Size 10012 Ratio 1/10 Load [daN] Worm Threaded screw spindle rotation translation speed speed ωv [rpm] v [mm/min] 1500 1800 1000 1200 750 900 500 600 300 360 100 120 50 60

40000 Pi Mtv [kW] [daNm]

30000 Pi Mtv [kW] [daNm]

25000 Pi Mtv [kW] [daNm]

20000 Pi Mtv [kW] [daNm]

15000 Pi Mtv [kW] [daNm]

10000 Pi Mtv [kW] [daNm]

5000 Pi Mtv [kW] [daNm]

65,4 43,6 32,7 21,8 13,1 4,36 2,18

49,0 32,7 24,5 16,4 9,80 3,27 1,64

40,8 27,2 20,4 13,6 8,17 2,72 1,36

32,7 21,8 16,4 10,9 6,54 2,18 1,09

24,5 16,4 12,3 8,16 4,90 1,64 0,82

16,4 10,9 8,16 5,45 3,27 1,09 0,55

8,16 5,45 4,08 2,73 1,64 0,55 0,28

42,5 42,5 42,5 42,5 42,5 42,5 42,5

31,8 31,8 31,8 31,8 31,8 31,8 31,8

26,5 26,5 26,5 26,5 26,5 26,5 26,5

21,2 21,2 21,2 21,2 21,2 21,2 21,2

15,9 15,9 15,9 15,9 15,9 15,9 15,9

10,6 10,6 10,6 10,6 10,6 10,6 10,6

5,30 5,30 5,30 5,30 5,30 5,30 5,30

Ratio 1/30 Load [daN] Worm Threaded screw spindle rotation translation speed speed ωv [rpm] v [mm/min] 1500 600 1000 400 750 300 500 200 300 120 100 40 50 20

54

40000 Pi Mtv [kW] [daNm]

30000 Pi Mtv [kW] [daNm]

25000 Pi Mtv [kW] [daNm]

20000 Pi Mtv [kW] [daNm]

15000 Pi Mtv [kW] [daNm]

10000 Pi Mtv [kW] [daNm]

5000 Pi Mtv [kW] [daNm]

32,7 21,8 16,4 10,9 6,54 2,18 1,09

24,5 16,4 12,3 8,17 4,90 1,64 0,82

20,4 13,6 10,2 6,81 4,08 1,36 0,68

16,4 10,9 8,17 5,45 3,27 1,09 0,55

12,3 8,17 6,13 4,09 2,45 0,82 0,41

8,17 5,45 4,09 2,72 1,64 0,55 0,28

4,09 2,72 2,05 1,36 0,82 0,28 0,14

21,3 21,3 21,3 21,3 21,3 21,3 21,3

15,9 15,9 15,9 15,9 15,9 15,9 15,9

13,3 13,3 13,3 13,3 13,3 13,3 13,3

10,7 10,7 10,7 10,7 10,7 10,7 10,7

7,99 7,99 7,99 7,99 7,99 7,99 7,99

5,32 5,32 5,32 5,32 5,32 5,32 5,32

2,66 2,66 2,66 2,66 2,66 2,66 2,66

Size 12014 Ratio 1/10 Load [daN] Worm Threaded screw spindle rotation translation speed speed ωv [rpm] v [mm/min] 1500 2100 1000 1400 750 1050 500 700 300 420 100 140 50 70

60000 Pi Mtv [kW] [daNm]

50000 Pi Mtv [kW] [daNm]

40000 Pi Mtv [kW] [daNm]

30000 Pi Mtv [kW] [daNm]

20000 Pi Mtv [kW] [daNm]

15000 Pi Mtv [kW] [daNm]

10000 Pi Mtv [kW] [daNm]

121 80,7 60,1 40,3 24,2 8,07 4,04

101 67,3 50,5 33,6 20,2 6,73 3,36

80,7 53,8 40,4 26,9 16,1 5,38 2,69

60,6 40,4 30,3 20,2 12,1 4,04 2,02

40,4 26,9 20,2 13,5 8,07 2,69 1,35

30,3 20,2 15,2 10,1 6,06 2,02 1,01

20,2 13,5 10,1 6,73 4,04 1,35 0,67

78,6 78,6 78,6 78,6 78,6 78,6 78,6

65,6 65,6 65,6 65,6 65,6 65,6 65,6

52,4 52,4 52,4 52,4 52,4 52,4 52,4

39,3 39,3 39,3 39,3 39,3 39,3 39,3

26,2 26,2 26,2 26,2 26,2 26,2 26,2

19,7 19,7 19,7 19,7 19,7 19,7 19,7

13,1 13,1 13,1 13,1 13,1 13,1 13,1

Ratio 1/30 60000 Pi Mtv [kW] [daNm]

50000 Pi Mtv [kW] [daNm]

40000 Pi Mtv [kW] [daNm]

30000 Pi Mtv [kW] [daNm]

20000 Pi Mtv [kW] [daNm]

15000 Pi Mtv [kW] [daNm]

10000 Pi Mtv [kW] [daNm]

62,5 41,5 31,2 20,8 12,5 4,10 2,05

52,0 34,6 26,0 17,3 10,4 3,42 1,71

41,6 27,7 20,8 13,8 8,32 2,73 1,37

31,2 20,8 15,6 10,4 6,24 2,05 1,03

20,8 13,9 10,4 6,92 4,16 1,37 0,69

15,6 10,4 7,80 5,20 3,12 1,03 0,52

10,4 6,92 5,20 3,46 2,08 0,68 0,34

40,5 40,5 40,5 40,5 40,5 40,5 40,5

33,8 33,8 33,8 33,8 33,8 33,8 33,8

27,0 27,0 27,0 27,0 27,0 27,0 27,0

20,3 20,3 20,3 20,3 20,3 20,3 20,3

13,5 13,5 13,5 13,5 13,5 13,5 13,5

10,2 10,2 10,2 10,2 10,2 10,2 10,2

6,75 6,75 6,75 6,75 6,75 6,75 6,75

55

power tables

Load [daN] Worm Threaded screw spindle rotation translation speed speed ωv [rpm] v [mm/min] 1500 700 1000 466 750 350 500 233 300 140 100 46 50 23

Size 14014 Ratio 1/12 Load [daN] Worm Threaded screw spindle rotation translation speed speed ωv [rpm] v [mm/min] 1500 1750 1000 1166 750 875 500 583 300 350 100 116 50 58

80000 Pi Mtv [kW] [daNm]

60000 Pi Mtv [kW] [daNm]

40000 Pi Mtv [kW] [daNm]

30000 Pi Mtv [kW] [daNm]

20000 Pi Mtv [kW] [daNm]

10000 Pi Mtv [kW] [daNm]

5000 Pi Mtv [kW] [daNm]

143 95,3 71,5 47,6 28,6 9,48 4,73

107 71,5 53,6 35,7 21,5 7,11 3,56

71,5 47,6 35,8 23,8 14,3 4,74 2,37

53,6 35,7 26,8 17,9 10,8 3,56 1,78

35,8 23,9 17,9 11,9 7,15 2,37 1,19

17,9 11,9 8,94 5,96 3,58 1,19 0,60

8,94 5,96 4,47 2,98 1,79 0,60 0,30

92,9 92,9 92,9 92,9 92,9 92,9 92,9

69,6 69,6 69,6 69,6 69,6 69,6 69,6

46,5 46,5 46,5 46,5 46,5 46,5 46,5

34,8 34,8 34,8 34,8 34,8 34,8 34,8

23,3 23,3 23,3 23,3 23,3 23,3 23,3

11,7 11,7 11,7 11,7 11,7 11,7 11,7

5,81 5,81 5,81 5,81 5,81 5,81 5,81

Ratio 1/36 Load [daN] Worm Threaded screw spindle rotation translation speed speed ωv [rpm] v [mm/min] 1500 583 1000 388 750 291 500 194 300 116 100 38 50 19

56

80000 Pi Mtv [kW] [daNm]

60000 Pi Mtv [kW] [daNm]

40000 Pi Mtv [kW] [daNm]

30000 Pi Mtv [kW] [daNm]

20000 Pi Mtv [kW] [daNm]

10000 Pi Mtv [kW] [daNm]

5000 Pi Mtv [kW] [daNm]

76,1 50,6 38,1 25,4 15,2 4,97 2,49

57,1 38,0 28,6 19,1 11,4 3,73 1,87

38,1 25,3 19,1 12,7 7,59 2,49 1,25

28,6 19,0 14,3 9,51 5,69 1,87 0,94

19,1 12,7 9,51 6,34 3,80 1,25 0,63

9,51 6,33 4,76 3,17 1,90 0,63 0,32

4,76 3,17 2,38 1,59 0,95 0,32 0,16

49,4 49,4 49,4 49,4 49,4 49,4 49,4

37,1 37,1 37,1 37,1 37,1 37,1 37,1

24,8 24,8 24,8 24,8 24,8 24,8 24,8

18,6 18,6 18,6 18,6 18,6 18,6 18,6

12,4 12,4 12,4 12,4 12,4 12,4 12,4

6,18 6,18 6,18 6,18 6,18 6,18 6,18

3,10 3,10 3,10 3,10 3,10 3,10 3,10

Size 16016 Ratio 1/12 Load [daN] Worm Threaded screw spindle rotation translation speed speed ωv [rpm] v [mm/min] 1500 2000 1000 1333 750 1000 500 667 300 400 100 133 50 66,6

100000 Pi Mtv [kW] [daNm]

80000 Pi Mtv [kW] [daNm]

60000 Pi Mtv [kW] [daNm]

40000 Pi Mtv [kW] [daNm]

30000 Pi Mtv [kW] [daNm]

20000 Pi Mtv [kW] [daNm]

10000 Pi Mtv [kW] [daNm]

218 145 109 72,6 43,6 14,5 7,26

174 116 87,0 58,1 34,9 11,6 5,81

131 87,0 65,4 43,6 26,1 8,71 4,36

87,0 58,0 43,6 29,0 17,4 5,81 2,90

65,0 43,6 32,7 21,8 13,1 4,36 2,18

43,6 29,0 21,8 14,5 8,71 2,90 1,45

21,8 14,5 10,9 7,26 4,36 1,45 0,73

141 141 141 141 141 141 141

113 113 113 113 113 113 113

85,0 85,0 85,0 85,0 85,0 85,0 85,0

56,5 56,5 56,5 56,5 56,5 56,5 56,5

42,5 42,5 42,5 42,5 42,5 42,5 42,5

28,3 28,3 28,3 28,3 28,3 28,3 28,3

14,2 14,2 14,2 14,2 14,2 14,2 14,2

Ratio 1/36 100000 Pi Mtv [kW] [daNm]

80000 Pi Mtv [kW] [daNm]

60000 Pi Mtv [kW] [daNm]

40000 Pi Mtv [kW] [daNm]

30000 Pi Mtv [kW] [daNm]

20000 Pi Mtv [kW] [daNm]

10000 Pi Mtv [kW] [daNm]

121 80,7 60,5 40,4 24,2 8,06 4,03

96,8 64,5 48,5 32,3 19,4 6,45 3,22

72,6 48,4 36,3 24,2 14,5 4,84 2,42

48,4 32,3 24,2 16,1 9,68 3,22 1,61

36,3 24,2 18,2 12,1 7,26 2,42 1,21

24,2 16,1 12,1 8,07 4,84 1,61 0,81

12,1 8,07 6,05 4,03 2,42 0,81 0,41

78,6 78,6 78,6 78,6 78,6 78,6 78,6

62,8 62,8 62,8 62,8 62,8 62,8 62,8

47,2 47,2 47,2 47,2 47,2 47,2 47,2

31,5 31,5 31,5 31,5 31,5 31,5 31,5

23,6 23,6 23,6 23,6 23,6 23,6 23,6

15,7 15,7 15,7 15,7 15,7 15,7 15,7

7,86 7,86 7,86 7,86 7,86 7,86 7,86

57

power tables

Load [daN] Worm Threaded screw spindle rotation translation speed speed ωv [rpm] v [mm/min] 1500 666 1000 444 750 333 500 222 300 133 100 44 50 22

Size 20018 Ratio 1/12 Load [daN] Worm Threaded screw spindle rotation translation speed speed ωv [rpm] v [mm/min] 1500 2250 1000 1500 750 1125 500 750 300 450 100 150 50 75

150000 Pi Mtv [kW] [daNm]

130000 Pi Mtv [kW] [daNm]

100000 Pi Mtv [kW] [daNm]

80000 Pi Mtv [kW] [daNm]

50000 Pi Mtv [kW] [daNm]

25000 Pi Mtv [kW] [daNm]

10000 Pi Mtv [kW] [daNm]

350 237 179 122 75,0 26,8 13,8

284 192 146 98,9 60,4 21,8 11,2

219 148 112 75,9 46,4 16,7 8,63

175 119 89,4 60,7 37,1 13,3 6,90

110 73,9 55,8 37,9 23,2 8,37 4,31

54,5 36,9 27,9 18,9 11,6 4,18 2,16

21,8 14,7 11,1 7,60 4,64 1,67 0,86

239 239 239 239 239 239 239

197 197 197 197 197 197 197

149 149 149 149 149 149 149

119 119 119 119 119 119 119

74,4 74,4 74,4 74,4 74,4 74,4 74,4

37,2 37,2 37,2 37,2 37,2 37,2 37,2

14,9 14,9 14,9 14,9 14,9 14,9 14,9

Ratio 1/36 Load [daN] Worm Threaded screw spindle rotation translation speed speed ωv [rpm] v [mm/min] 1500 750 1000 500 750 375 500 250 300 150 100 50 50 25

58

150000 Pi Mtv [kW] [daNm]

130000 Pi Mtv [kW] [daNm]

100000 Pi Mtv [kW] [daNm]

80000 Pi Mtv [kW] [daNm]

50000 Pi Mtv [kW] [daNm]

25000 Pi Mtv [kW] [daNm]

10000 Pi Mtv [kW] [daNm]

187 124 93,6 63,0 37,4 11,9 6,40

109 74,3 57,9 39,8 25,6 10,4 5,55

83,4 57,2 44,5 30,6 19,7 7,95 4,26

66,7 47,7 35,6 24,5 15,8 6,36 3,41

41,7 28,6 22,3 15,3 9,85 3,98 2,13

20,9 14,3 11,2 7,65 4,92 2,00 1,06

8,33 5,71 4,45 3,06 1,97 0,85 0,65

94,9 94,9 94,9 94,9 94,9 94,9 94,9

83,2 83,2 83,2 83,2 83,2 83,2 83,2

64,1 64,1 64,1 64,1 64,1 64,1 64,1

50,7 50,7 50,7 50,7 50,7 50,7 50,7

31,7 31,7 31,7 31,7 31,7 31,7 31,7

15,9 15,9 15,9 15,9 15,9 15,9 15,9

6,36 6,36 6,36 6,36 6,36 6,36 6,36

Size 25022 Ratio 1/12 Load [daN] Worm Threaded screw spindle rotation translation speed speed ωv [rpm] v [mm/min] 1500 2750 1000 1833 750 1375 500 916 300 550 100 183 50 92

200000 Pi Mtv [kW] [daNm]

180000 Pi Mtv [kW] [daNm]

150000 Pi Mtv [kW] [daNm]

130000 Pi Mtv [kW] [daNm]

100000 Pi Mtv [kW] [daNm]

80000 Pi Mtv [kW] [daNm]

50000 Pi Mtv [kW] [daNm]

543 368 278 189 115 41,7 21,4

489 331 250 170 104 37,5 19,3

407 276 208 141 86,4 31,2 16,1

353 240 180 122 75,1 27,1 13,9

271 184 139 94,2 57,8 20,8 10,7

217 147 111 75,6 46,2 16,6 8,59

135 92,0 69,5 47,2 28,8 10,4 5,37

370 370 370 370 370 370 370

332 332 332 332 332 332 332

276 276 276 276 276 276 276

240 240 240 240 240 240 240

185 185 185 185 185 185 185

148 148 148 148 148 148 148

92,2 92,2 92,2 92,2 92,2 92,2 92,2

Ratio 1/36 200000 Pi Mtv [kW] [daNm]

180000 Pi Mtv [kW] [daNm]

150000 Pi Mtv [kW] [daNm]

130000 Pi Mtv [kW] [daNm]

100000 Pi Mtv [kW] [daNm]

80000 Pi Mtv [kW] [daNm]

50000 Pi Mtv [kW] [daNm]

207 142 110 76,2 49,0 19,7 10,6

186 128 99,6 68,5 44,1 17,8 9,54

155 106 83,0 57,1 36,7 14,8 7,95

134 92,4 72,0 49,5 31,8 12,8 6,89

103 71,1 55,3 38,1 24,5 9,90 5,30

82,9 56,8 44,3 30,4 19,6 7,92 4,24

51,8 35,5 27,6 19,0 12,2 4,95 2,65

157 157 157 157 157 157 157

141 141 141 141 141 141 141

117 117 117 117 117 117 117

101 101 101 101 101 101 101

78,0 78,0 78,0 78,0 78,0 78,0 78,0

62,8 62,8 62,8 62,8 62,8 62,8 62,8

39,1 39,1 39,1 39,1 39,1 39,1 39,1

59